You might have frequently heard about the weld neck flange from the people associated with industries. It basically helps in reduction of stress at the bottom of the pipes. Weld neck flanges are mainly of two types. This includes one for gaskets and other for operative industrial plants. It is made up of circular parts which extend further with rim circumference and then welded with pipe. The rim here contains many holes which can benefit from bolted attachments. Thus, it proves structurally more beneficial to industries.

What is a weld neck flange?

Weld neck flanges are used mainly for making one structural unit with sloped neck and weld butt connections in pipe. Due to its unique design, the stress gets transferred to the base instead of the neck which is important to connect vessels. These are mostly demanded for the high-stress applications like ASME pressure vessels. Internal diameter is made to match with flow of fluid in the pipe thus, reducing friction. It is made of many types of materials as mentioned below.

Carbon steel (with GI/without GI)

Cast iron

Copper

Aluminum

Which are the different types of Weld Neck Flanges?

You might strike with many different weld neck flange types. It includes options like raised face, Ring Type Joint (RTJ),Orifice flange and more. You can select the best suitable type according to your requirements along with flange specifications. Let’s make a quick overview for each of the types which helps you in making the best decision.

Standard Weld Neck Flange

This type is specifically designed with a lengthy conical neck through butt with pipe ultimately making the joint stronger. Also, it helps to spread out the stress produced on pipe for effective longevity.

Reduced weld neck flange

It is mainly not considered as a different type of weld neck flange. Instead the type indicates pipes of various fittings ultimately reducing size from larger to smaller one. Reduced flange has different diameters on both sides of the pipe. It will ultimately help to joint pipes having different diameters.

Long weld neck flange

It is the enlarged version for mostly used welding neck flanges. Long weld neck flanges are used in columns and barrels as nozzles. This is mainly of two types designed for best usage.

LWN heavy barrel

Equal LWN barrel

Both of these types have unique shapes and beneficial wall structure.

NW long weld neck flange

NW long neck flanges are preferably used in vacuum systems. It is characterized with a tapering long neck made with high quality stainless steel materials. These designs help to improve stiffness and durability for a high vacuum facility. The flanges are directly incorporated on the surface of the vacuum chamber, ensuring an airtight system. These are available in markets with different sizes ranging from NW10 to NW50. Each of these differ from others with different diameter and patterns of bolts.

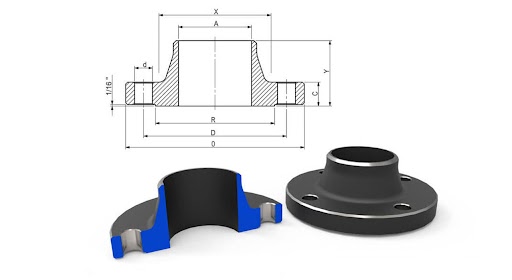

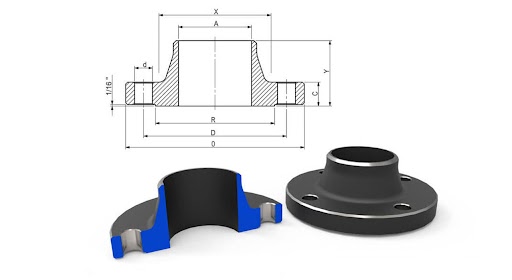

Dimensions of weld neck flange

Various weld neck flange dimensions are available which range from ½” to 24” in the market. Each of the flange lands has a different diameter outside as well as inside. This leads to increase in face thickness and other bolt holes. Among all, the smallest size of diameter on the outer side has 89mm and about four holes. On the other hand, the largest size available is 1565mm with a face thickness of about 271mm.

Use of weld neck flange with its different applications

Weld neck flange application has become a focal point in the industrial environment due to its reliable nature and versatile property. Also, its simple design enables a person for easy installation and replacement benefits. There are various potential uses of weld neck flange depending upon its welding techniques.

Basically it is used for fittings in different pipes and connections of the same. The flanges are used for making a reliable connection between two tubes or pipes. Also, it is preferable to link valves and other parts in the piping system. It is even useful in chemical plant industries, water and oil rigs for better connection.

Weld Neck flange comes with different schedules

Depending upon the pipe wall thickness, weld neck flanges are further categorized in schedule. For particular nominal bore, different weld neck flanges will have different inner diameter. This is just to match with the connected pipe for smooth flow of fluids inside. SCH 40 and SCh 80 are widely used, but sometimes SCH 120, 140, 160 are required for higher pressure line connections where pipe wall thickness is higher to withstand pressure and stress.

Benefits of using Weld neck flange

Let’s quickly consider benefits to enjoy from weld neck flange

Leak resistance

Weld neck flange is highly precise which ensures a tight sealing in between two pipes. This ultimately gives safety for leak resistance.

Superior strength

Due to its effective design, weld neck flanges are incredibly strong which can withstand high pressure and temperature conditions. These are essential to integrate along with threaded or slip on styles for getting superior integrity.

Enhanced durability

The flanges are available with different sizes and shapes in the market. Also, these have considerably more lifespan because of corrosion resistance, effective against wear and erosion.

Reduce stress concentration

Flanges improve the transition of stress to pipes leading to reduction in cracks and failures. In short, it passes the stress concentration from the neck of the pipe to base leading to higher longevity.

Lesser need of maintenance

There is very less chance of development of cracks and failures. It indeed suggests the lesser need of maintenance with weld neck flange as compared to other options.

Improvement in flow characteristics

The smooth design of bore in weld neck flange leads to reduction in pressure drop and turbulence of fluid flow. This ultimately enhanced the fluid flow without any obstruction.

Strong and reliable

Weld neck flange helps to increase the face thickness of pipe from weld part till flange. The thickness in design assures to transfer the internal pressure of fluid flow to the pipe. This will make the spreading of stress generated instead of targeting a particular area making it a more reliable and strong option.

Easy to align, install and test

Weld neck flanges are easily aligned with installation along with pipe and robust to remove also. It is very easy to test the integrity of weld using radiography due to the design of the weld neck flange.

Conclusion

You might now have reaffirm the use of weld neck flange in industries for improved benefits. It is proven as a once in a while investment which needs less maintenance as well as other costs. There are available different types of weld neck flange with varied dimensions and application. Therefore, you should definitely work upon your decision to install a weld neck flange.

Frequently asked question

Is weld neck flange useful for flat face flange?

Yes, weld neck flanges are proven options for flat face flanges. This helps to provide flexibility and specifically used as per requirement with piping system

Are weld neck easy to install options?

It might become tricky to install a weld neck flange for the first time. But the task becomes easy when welders and trained people are at place with expertise and skills. It is important to mark a proper alignment of welding during installations.

Can weld neck flange prove worth installing in the long term?

You might find a weld neck flange a bit costlier option initially. But it can definitely prove a worth to install option at long term due to its durability and reliability features. Also, it needs less maintenance and downtime once installed properly.