Flanges are the most important part in the industry which allows connection fittings over pipes with different diameters. You would definitely have heard about the Tongue and Groove flanges. These are one among the widely used flanges in various piping systems. These are designed typically to join various pipes, valves and other fittings. The unique feature of Tongue and Groove flange is to set up a tight seal which can easily withstand high temperature and high pressure conditions.

Here, two flanges get bolted together with a proper fixing of tongue into groove which ultimately gives a reliable sealing. Hence, the specific design plays an important role to prevent leakage in the system carrying fluids or gasses from the joint area. Let’s explore more about Tongue and groove flanges in this blog.

What is Tongue and Groove Flanges?

Tongue and Groove flanges are the popular choice in industry for piping systems. It is mainly used in the connection of valves, pumps, pipes and other equipment. The specific design of the Tongue and Groove flanges makes it an ideal system which provides a tight as well as leak proof sealing. You can find the flange in various shapes like round, hollow, forged and hex bars. Hence, these are widely applicable in industrial areas facing high temperature and pressure environments. The design is particularly made of following two types:

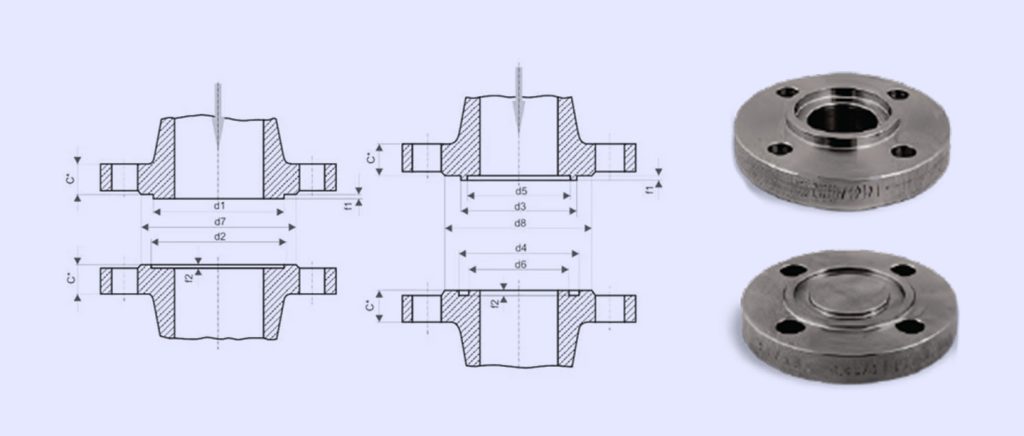

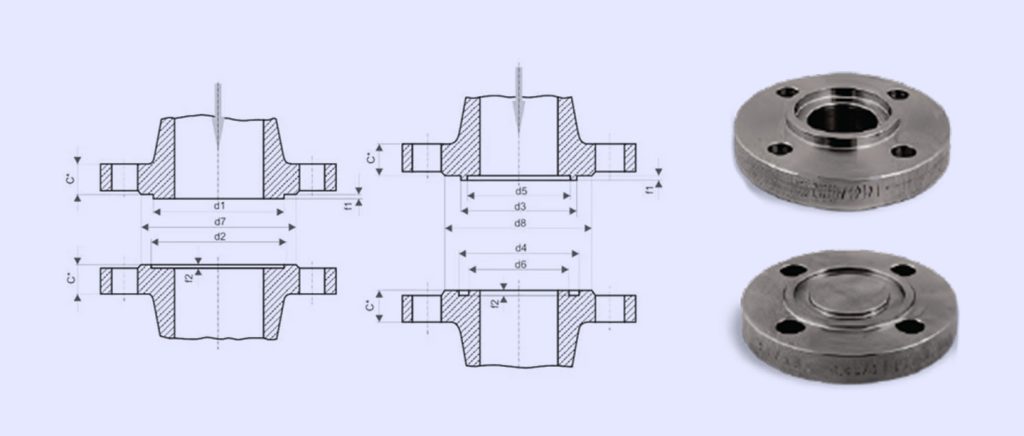

Tongue [raised surface]

The raised surface of the flange is called the tongue. It has specific dimensions which particularly fits into the groove of other mating flanges.

Groove [Recessed surface]

The other mating flange contains a matching recessed surface. It is particularly called a groove. The groove is designed in a particular way which fits with the tongue for ensuring a secured sealing and fit of flanges.

Due to such design Tongue and Groove flanges impart many advantages like reduced leakage chances, reusability and enhanced sealing. Hence, applied in many of the industrial areas which need frequent assembly with need of reliable seal.

Features of Tongue and Groove flanges

Tongue and Groove flanges are the best example of precise engineering which offer a combination of various features. It includes reliable sealing benefits, durable materials and more. All of such feature makes the Tongue and Groove flange an indispensable components in industrial piping system to give a reliable sealing. Check out these mesmerizing features of Tongue and Groove flanges.

Precision engineering

The flanges are designed and manufactured using precise dimensions and tolerance levels. Therefore, it gives excellent fit and proper alignment during installation. It is very important for the proper alignment of the mating flanges to prevent the failure of the sealing. Hence, the precise engineering used in Tongue and Groove flanges minimizes the issues of misalignment or gaps in between the mating flanges. Due to this feature, Tongue and Groove flanges are kept on the priority when it comes to seek for the reliable sealing in the piping system.

Material selection

Tongue and Groove flanges are made from the materials like stainless steel, exotic steel or alloy steel, carbon steel etc. These materials have the property of durability, corrosion resistance and high mechanical strength. Thus, Tongue and Groove flanges made out of this material can easily tolerate all harsh environmental conditions in industries. Also, these are suitable to install in a piping system carrying corrosive fluids or facing high temperature and pressure.

Sealing Mechanism

You can find here a unique design in the mating flanges. Here one lies with a protruding part called tongue and another flange contains the groove. The two flanges are mated and bolted together where tongue fits tightly into the groove making a tight sealing system. The sealing mechanism works to minimize the chances of leakage. Therefore, the feature avails the Tongue and Groove flanges as preferable choice for application in areas where preventing leaks is crucial while passing specific fluid or gas.

Versatility

Tongue and Groove flanges are mostly compatible with a wider range of piping systems and different components too. Therefore, these are widely applicable in different industries. It mainly includes oil and gas, power generation, chemical processing and more. Versatility and compatibility with different components makes Tongue and Groove flanges a much higher choice for different industries.

Resistance to extreme conditions

Tongue and Groove flanges are designed mainly to tolerate high temperature and pressure conditions encountered with industrial processes. It allows a robust construction and makes a secured sealing mechanism which helps to maintain a proper integrity. Hence, it helps in making operating conditions which helps in contributing for safety and efficiency for the piping system.

Testing and certification

Tongue and Groove flanges of high quality undergo rigorous testing whenever installed. Hence, it can ensure to meet particular industrial specifications and standards. The testing particularly includes material analysis, pressure testing and even dimensional inspection. Also, there are many quality assurance measures which make a reliable sealing.

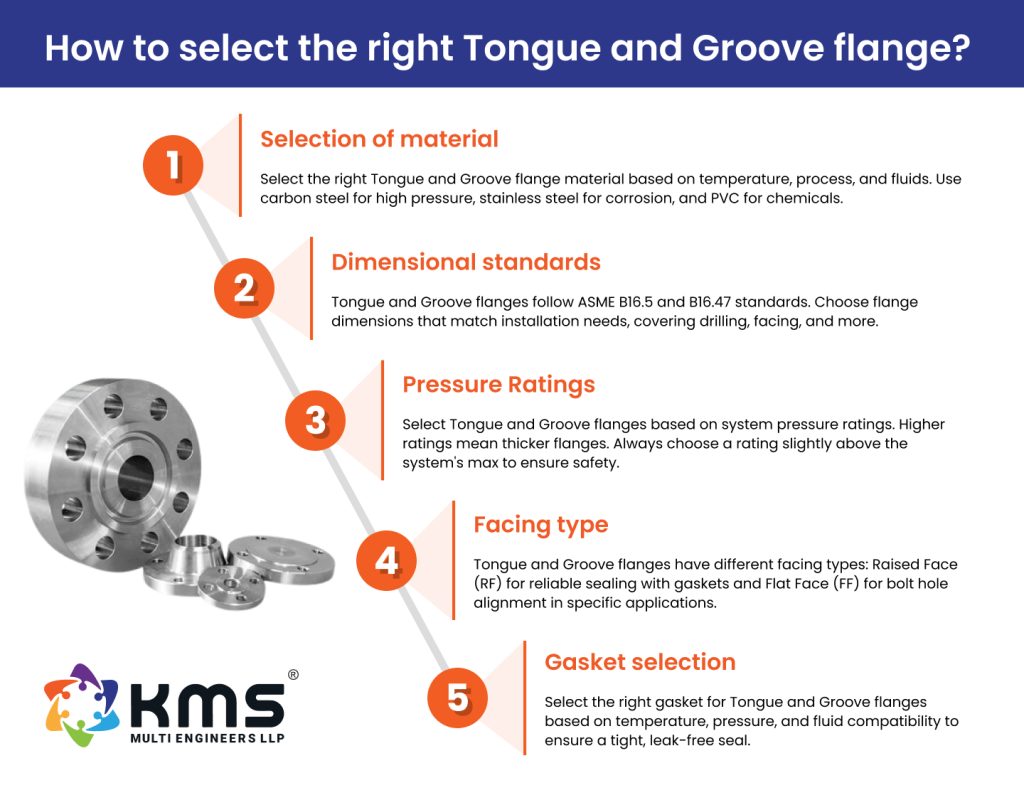

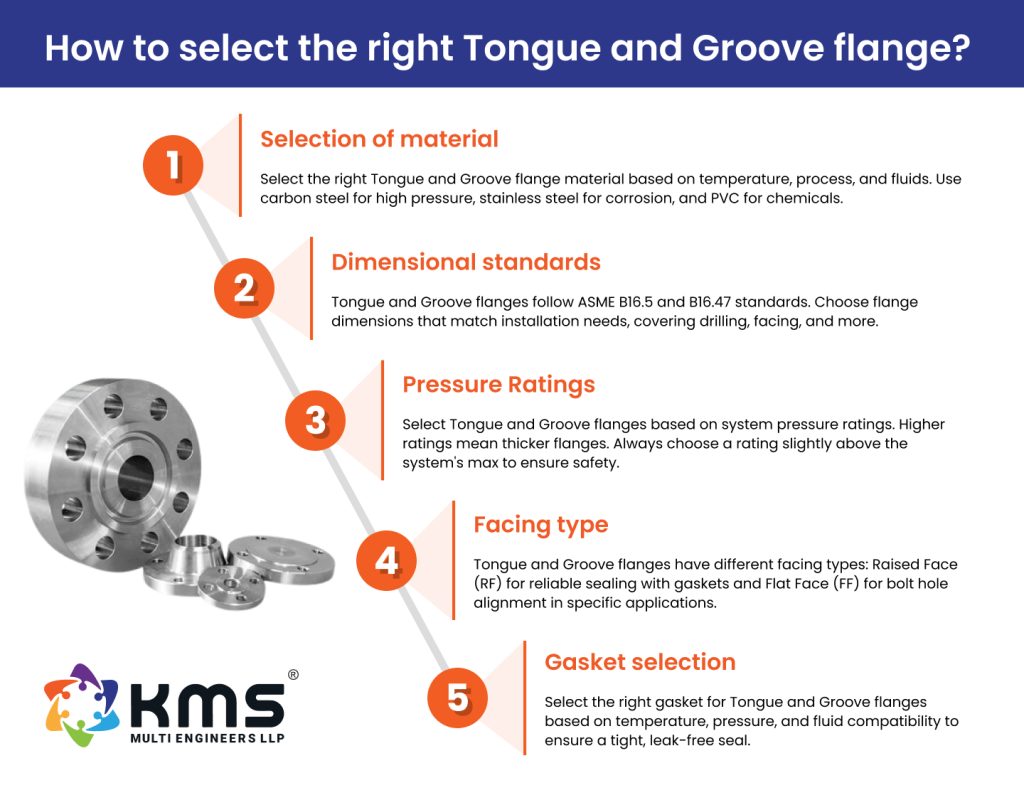

How to select the right Tongue and Groove flange?

There are many of the factors needed to consider before choosing a particular Tongue and Groove flange for installation. Refer these factors mentioned as follows:

Selection of material

Firstly you need to undertake the proper selection of Tongue and Groove flange material. To select the right material consider the criteria like temperature, operating process and other transported fluids. Generally, Tongue and Groove flanges are available in materials like stainless steel, carbon steel, PVC and more. Prefer the selection of flange made from the carbon steel when it requires the installation at high pressure areas. Stainless steel is opted when the flange needs to tolerate the corrosion. However, PVC is applied when transportation of chemicals takes place through pipes. Additionally, it is suitable for the low pressure area too.

Dimensional standards

Tongue and Groove flanges are manufactured using specific dimensional standards. Commonly the dimensional standard applicable to this standard is ASME B16.5 and ASME B16.47. These standards define the specification like drilling, flange dimension, facing requirements and more. Hence, it is important to choose the flange dimension which should match the specific requirement of the installation area.

Pressure Ratings

You need to select the flange as per pressure ratings which a system could maximally face. Tongue and Groove flanges are available in high pressure rating classes. Generally, the design of the flange gets thicker as the pressure rating increases. Remember to select the pressure rating flange of bit higher than of the system to avoid any sort of accidents.

Facing type

The facing type of the Tongue and Groove flange means how shaping of the flange is initiated and finished. Raised Face [RF] and Flat face [FF] are some of the common and widely used facing types of flanges. Raised face flanges have the particular design which aligns with the gasket to give a reliable sealing of the system. This feature makes the RF flanges suitable for application in most areas. Flat face flanges are applied when it is important to undertake the bolt hole alignment.

Gasket selection

Gasket plays a very important role when it comes to Tongue and Groove flange. You need to select the gasket material based on specific temperature and pressure operation of a particular area of installation. Also, check the compatibility of the gasket with the fluid flowing via pipe. Gaskets are made generally of materials like Teflon, graphite, rubber, metal and more. Hence, the selection of the gasket is an important factor to consider for achieving tight seal without any worries of leakage.

Benefits of Tongue and Groove flanges

There are many of the benefits to enjoy once after installation of the Tongue and Groove flanges. Check out these exciting benefits as follows:

Easier installation

Enjoy the easy installation of the Tongue and Groove flanges unlike traditionally available flat flanges. The easy installation is tagged to this flange as it doesn’t require any sort of bolting or welding. Simply the two mating flanges as tongue and groove slides over one another to hold tightly in place. This unique design makes the installation easy and quick installation which readily saves time and money.

Improved sealing capabilities

Tongue and Groove are the ideal choice in the industries when it comes with the requirement of reliable sealing. The two different pieces of the flange get snug together which helps in creation of the reliable seal which minimizes the seepage or leakages. The Tongue and Groove flange design ensures that two pieces stay buckled up at their place. Therefore, it is able to tolerate high pressure and temperature conditions.

Reduced Corrosion

Tongue and groove flanges also have the capacity to reduce the corrosion in the piping system. I8t is achieved due to reliable sealing observed with two pieces. It minimizes the flow of the water through any cracks or crevices that might prove a source of corrosion. Also, there is no involvement of welding during installation of Tongue and Groove flanges which reduces the chances of galvanic corrosion. This generally happens when mixing of the dissimilar metals comes in contact with each other.

Increased strength

Tongue and Groove flanges come with interlocking design which is perfect for creating a strong connection. These are much beneficial to apply in different high pressure and temperature conditions areas. Increased strength ensures to make the pipe secured at a position even under the extreme conditions.

Cost savings

Tongue and Groove flanges are great when it comes to cost savings due to improved sealing and ease of installation. Also, there is no need to carry out additional processes of welding or bolting which ultimately reduce the labor cost as compared with traditional flange. Tongue and Groove flanges are best for reduction of overall cost due to lesser need of repair and maintenance.

Application of Tongue and Groove flange

The effective design helps to ensure the leak proof system which makes it applicable in various industries some of which are as follows:

Oil and gas industry

Tongue and Groove flanges have the ability for maintaining the highly reliable seal in high temperature and pressure conditions making it widely used in oil and gas industries.

Chemical plants

Hazardous substances require a secure and reliable sealing to prevent leaks in the system. Therefore, Tongue and Groove flanges are commonly used to transport such chemicals.

Power generation

Power generation industries need to deal with condensate systems and streams which indeed demand for the connection which could withstand typical environments of high temperature and pressure.

Liquefied natural gas systems

Tongue and Groove flanges are applicable in piping system which needs to transport the liquefied natural gas. It is because of the feature to prevent leaks in much low temperature environmental conditions.

Heavy machinery in hydraulic system

Heavy machinery installed in the hydraulic system creates the high pressure conditions which is tolerable only with application of Tongue and Groove flanges. It doesn’t allow the hydraulic fluid to leak which maintains the safety and efficiency of the system.

Pharmaceutical and Biotechnology industries

Pharmaceutical and Biotechnology industries make a great demand for sterilization as well as vacuum conditions. Therefore, Tongue and Groove flanges are applied to create a leak proof system in such industries.

FAQs

What is the role of Tongue and Groove flange in the piping system?

Generally, in the piping system, Tongue and Groove flanges are used to connect the pipe together giving a reliable sealing and other types of fittings too.

What is the dimension of the Tongue and Groove flange?

Mostly, Tongue and Groove flanges are available in ⅓ width and full joint depths. Also, these are available in varying widths of 1.5 to 3.5 and depths of about 75” to 3.5’.

What is the purpose of Tongue and Groove?

Tongue and Groove flanges are generally installed to get edge to edge joining, fit with similar objects, flooring and other similar construction.

What is the length of Tongue and Groove flanges?

Tongue and Groove flanges have length of about 3 m to 5.4 m including treated and untreated mixture.

What is the cost of installation for Tongue and Groove flanges?

The average cost for installation of the Tongue and Groove flanges ranges from $1350 to $2250.