Installing flanges in piping systems needs precision. A single mistake can lead to leakage and damage. What if there was a flange that doesn’t require high precision for installation? Wouldn’t it be better?

This is where the slip-on flange comes into the picture. You don’t have to precisely align the flange while installation. They are easy to install and maintain.

In this blog, we are going to discuss slip-on flanges, their advantages, and how they differ from other types of flanges.

So, let’s start with what is slip-on flanges.

What is a slip-on flange?

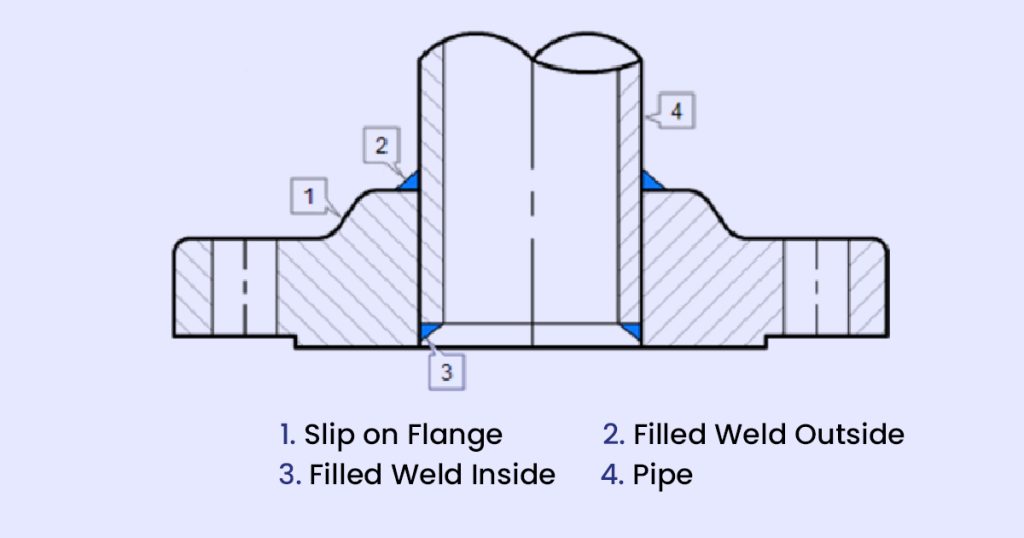

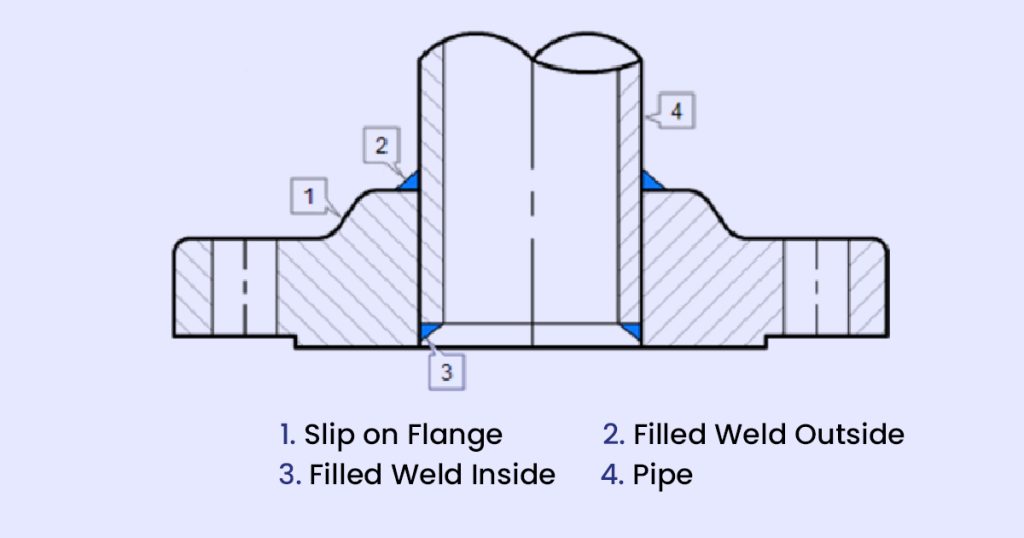

As the name suggests, a slip-on flange is designed to slide over the end of the pipes. These flanges are slightly bigger in diameter than the pipe outer diameter. So you can easily slide them.

Once you slide them over the pipe and place it the proper position and alignment, you can weld them. They should be welded from both ends. It is to make sure that they are reliable and safe to use.

There are many advantages of using slip-on flanges in piping systems. Let’s learn about them.

Advantages of Slip-on Flanges in Piping Systems

Ease of Installation

Slip-on flanges are very easy to install. You can just slide it in the pipe and then weld it. They require less precision in cutting the pipe to the right length, as slip-on flange slips over the pipe. Also, they can easily be aligned, reducing the time and labor costs needed for installation.

Cost-Effectiveness

Slip on flanges are affordable when compared to other flange types. You can buy them for low rates. And you don’t have to spend much money on installation. They are easy to install and maintain. It saves you labor costs and time as no surface preparation is required before welding like weld neck raised face flanges.

Less Material Requirements

Slip-on flanges are thinner and require less material for manufacturing. It makes them lighter and less expensive compared to other flanges like weld neck flanges. Also, the process is less complicated compared to weld neck flanges.

Reduced Leakage Risk

Slip-on flanges are slightly bigger in diameter than the pipe. When you properly weld it, it provides a reliable and tight seal. This seal helps reduce the leakage. It makes these flanges an ideal choice for handling fluids.

Flexibility in Applications

Slip-on flanges can be used under different conditions. You can use them in environments with low pressure and temperature. So, industries operating under low-risk environments can use slip-on flanges.

Use cases of Slip-on Flanges

Slip-on flanges are usually used in industries operating under low pressure and temperature requirements. Here are some examples of different industries using slip-on flanges with their use cases.

Water treatment and distribution

Generally, water treatment plants work under low-pressure conditions. So, slip-on flanges can be used in piping systems from one place to another. Slip-on flanges are easy to assemble and maintain. So water treatment plants can easily clean and maintain them. They can save companies time and money.

Commercial and residential HVAC system

Slip-on flanges are easy to install and repair. It makes it the best option for use in HVAC systems. They are generally used in ductwork and low-pressure gas lines, where cost efficiency and regular maintenance are very important.

Fire protection systems

Slip-on flanges are used in sprinkler systems and other fire protection equipment. They are important because fire protection systems require quick assembly. They are also cost-effective, which is important as fire protection systems are important in fire conditions.

Light industrial manufacturing

Light industrial manufacturing companies use slip-on flanges in their compressed air and low-pressure stream systems. For example, the Textile industry uses them in compressed air systems to make sure that the machinery runs smoothly. These flanges are quick to install and low cost making it a best choice for light industrial manufacturing companies.

How Slip on flanges are different than other type of flanges?

Slip-on flanges differ from other types of flanges in many ways. Here is a list of few parameters that makes slip-on flanges different.

Design and installation:

Slip-on flanges let you slide the flange in the pipe to align it easily and install it faster. Other flanges, like weld neck flanges, directly connect to the pipe which needs precision. But slip-on flanges don’t really need precision. They are more flexible by design.

Cost and material:

Other flanges, like weld neck and blind flanges, are costly compared to slip-on flanges. Slip-on flanges are thin and light. They use less material to manufacture. It makes them affordable, and the use of less material also makes installation easy.

Strength and durability:

Slip-on flanges are designed to operate under low pressure and temperature conditions. So, they are the best choice among all the flanges that operate under low pressure and temperature conditions.

Sealing capability:

Most flanges are welded from a single end. But slip-on flanges are welded from both the inside and outside. It creates a strong seal and prevents leakage.

In short, slip on flanges are the best choice to operate under low pressure and temperature conditions. Now that we have seen the advantages and use cases of slip-on flanges, lets take a look at some tips to install and maintain them.

Installation tips for slip-on flanges

Check everything before installation:

Clean both the pipe and the flange. Remove if there is any oil or dirt. Make sure there is no damage that looks for any damage that can affect a proper fit or sealing. If you are using raised face flanges, you must ensure that it has proper serrations. So the gasket can fit easily, and leakage can be avoided. Generally, concentric serration is preferred, but sometimes non concentric raised faces are also used. Concentric raise face should be generally 125AARH.

Slip on the flange:

Slide the flange over the end of the pipe. It is always better to align it properly. Flanges with bigger diameters help you do it smoothly.

Align and position:

properly align your pipe and flange in the correct position. It can help you with even welding.

Welding:

Slip on flange welding from both the inside and the outside. Look for manufacturer guidelines when using a welding material. It ensures that your welding is smooth and durable.

Maintenance tips for slip-on flanges

Here are four maintenance tips that can help you make your piping system durable and operate smoothly.

Routine inspections:

Check flanges regularly for any wear, corrosion, or damage. Make sure that welded areas don’t have any leakage.

Tighten and check bolts:

Tighten the bolts periodically to secure the flanges. Bolts sometimes loosen up due to vibration, so keep an eye on them.

Clean flange surfaces:

Regularly clean flanges so there is no rust or debris on them. It can help you maintain proper sealing without any leakage. Check manufacturer guidelines before using any solvents and cleaners.

Keep a log: After every maintenance or changing any components, write it down in a log. So, engineers from different shifts can know about the maintenance.

Conclusion

Slip-on flanges offer many advantages and are an ideal choice for industries operating under low pressure and temperature. By understanding how and when to use these flanges, you can ensure that your operations run smoothly without any machine downtime. Whether you are working on a new project or upgrading an existing one, slip-on flanges are an amazing choice to consider.

At KMS Engineers, we are a leading manufacturer and exporter of slip-on flanges. Our flanges are manufactured with industry and safety standards in mind. We offer a variety of flanges and piping equipment.

Call us at 07990688545 or email us at amit@kmsengineers.com and share your requirements for Slip-on flanges and other piping equipment.