Stainless steel is the most widely used metal in recent times. It can overcome other metals due to properties like high corrosion resistance, durability etc. Stainless steel flange is designed having a basic disc-shaped component. This can could lie under the ring or even plate type to form a ring at a particular end of pipe. Therefore, it is mostly applied in the pipeline industries. As the name suggests here there is use of stainless steel materials. The basic SS flanges material has 10.5% chromium minimum. The most common options are SS304 ( chromium 17.5% to 19.5% ,nickel 8% to 10.5% and other elements like manganese, Silicon, nitrogen, carbon ) and SS316 stainless steel (chromium 16% to 18%,Nickel 10% to 14%, Molybdenum 2% to 3%, silicon, carbon, nitrogen, sulphur, phosphorus). The addition of Molybdenum in SS316 grade gives more corrosive resistance and toughness over a wide range of temperatures.

When we come across SS304L or SS316L, here L denotes lower carbon content than usual SS304 or SS316 ,so it is softer and offers machinability and weldability. Each of these options provide the same corrosion resistance. If sometimes H is used, it shows higher carbon content which offers improved tensile strength while exposed to higher temperatures.

Thus it is further divided into various types each serving with specific functions. It includes types like blind flanges which helps to isolate the particular area sealing the end of the pipe. Also, there are specific standards for industrial selection of Stainless steel flanges like American Standards (ASME), DIN, ISO etc.

Explore this blog further to know detailed information of ss flanges type, feature and application.

Types of SS Flanges

Quickly check out the distinct types of the stainless steel flanges applicable for various uses.

Weld neck flanges

It is easily identifiable because of the characteristic of protruding neck in the design. These have similar dimensions of thickness and level of flange surface. Hence, it is applicable in areas facing high temperature and pressure conditions.

Slip-on flanges

Mark it under an affordable price range of flange available in the market. The flange is designed to have a slight more inner diameter as compared to pipe’s outer diameter. It will make the pipe slip-on into the flange easily. Further, these are fillet welded to make a secured connection with pipe. Thus, it proves an ideal application for the low pressure areas.

Blind flanges

Blind flanges are specifically designed for sealing the vessel or piping system. It doesn’t contain the bore in composition. These are perfect to seal in the system which requires frequent cleaning, inspection or maintenance. Blind flanges are enough to handle the high pressure and stress conditions.

Threaded flange

Threaded flanges are specially designed for a purpose of installation on a place where welding is not feasible. You need to install the stainless steel flanges with external threads. It is advised to install the threaded flanges in an area where low stress with high temperature and pressure is present.

Lap joint flanges

Lap joint flanges are part of slip on flanges. It is designed for application at the stub end of pipe. It is preferably applicable in piping systems which requires periodic maintenance and inspection.

Socket weld flanges

Socket weld flanges are easily applicable for the small diameter and high pressure giving areas. The socket weld flanges possess internal welding in the design. Hence, these are recognized for durable and incredible sealing in the piping system. Wide use of the socket flanges is seen in chemical processing industries.

Orifice flanges

Orifice flanges are specially installed in the piping system carrying specific liquid or gases. These are installed along with an orifice plate or flow nozzle for interrupted passage of fluids.

Ring joint type flanges

These flanges are indeed applicable in areas which face high temperature and pressure environments. It is made with a precise machine groove which could easily get combined with blind, slip-on or weld neck flange. RTJ flanges deliver the durable sealing which is applicable for leak proof sealing at high temperature and pressure.

You can choose any of the flange types depending on the need of the application. Prefer consideration of temperature, pressure classes and then finalize one.

Features of SS 304 Flanges

Flange SS 304 is widely applicable in different industries due to its various features. Explore these excellent features as follows:

Corrosion resistance

SS 304 flanges are resistant to harsh corrosive environments developed due to fluids flowing in the pipe. It has the presence of the stainless steel materials which remain inactive during exposure to any oxidation process, acids base, chlorines and more. Therefore, it is applicable in many industries like food and beverages, chemical processing, marine environment and more.

Durability

The connection with SS flanges is known for its strength and durability. It is achieved due to composition of the flange with high quality stainless steel material. These are easily applicable in high temperature and pressure conditions to ensure the reliable sealing without leaks.

Versatility

SS 304 flanges are landed in many different sizes and dimensions. Hence, it is applicable in a wide range of industries to get secured sealing in piping systems. This feature provides application of SS flanges even in machineries, pressure vessels and more.

Ease of fabrication

It has the feature to fabricate into different shapes and sizes with welding and machine grooves. Thus, you can prefer its application to meet specific requirements in the piping system.

Hygienic properties

In industries like food and beverages, pharma it is very crucial to maintain hygiene and cleanliness. Also, it is important to use the material which proves non-reactive to food supplements passing via pipe. SS flanges are non-reactive and non-toxic making it an ideal choice in this industry.

Aesthetic appeal

SS 304 flanges can provide an aesthetic look to an area with its smooth, shiny and attractive surface. Therefore, it is also applicable in areas which have concerns with the appearance of areas like architecture and other decorative projects.

Applications

SS 304 flanges have impressive properties like corrosion resistance, formability and ease of fabrication etc. Hence, these are applicable in various industries as follows:

Chemical and petrochemical industry

It is used in piping to transport corrosive fluids. In reactors and vessels, SS 304 flanges are utilised to handle corrosive substances.

Oil and gas industries

Offshore and onshore rigs make use of this flange to control the leaks in harsh environmental conditions. Refiners also use SS flanges in areas having high pressure and temperature conditions.

Food and beverage industries

It is applicable in areas like storage tanks, heat exchangers, and mixtures where there seems importance of maintaining hygiene. In the dairy industry it is used in milk processing containers.

Pharmaceutical industries

In pharmaceutical industries sterilisation and hygiene is a concern to avoid any contamination. It is achieved with installation of SS 304 flanges. These are also applicable in the packaging industries where sterilisation is mut.

Water treatment industries

It is used in different systems like desalination plants which help to resist the corrosion of saltwater. It is employed in different industries for treatment and transportation of purified water.

Construction industries

SS flanges offer the strength and corrosion resistance properties. Hence, it is also applicable in construction of bridges, buildings and infrastructure processes.

Power generation

Thermal and nuclear power plants are always exposed to high temperature and pressure conditions. Hence, it is mandatory to maintain a leak proof environment to prevent accidents. Also, it is applied in industries generating renewable sources of energy like wind and solar to get stiff and durable connections.

Installation and Maintenance

SS 304 flanges need the best practices of installation and maintenance to ensure the longevity of the system.

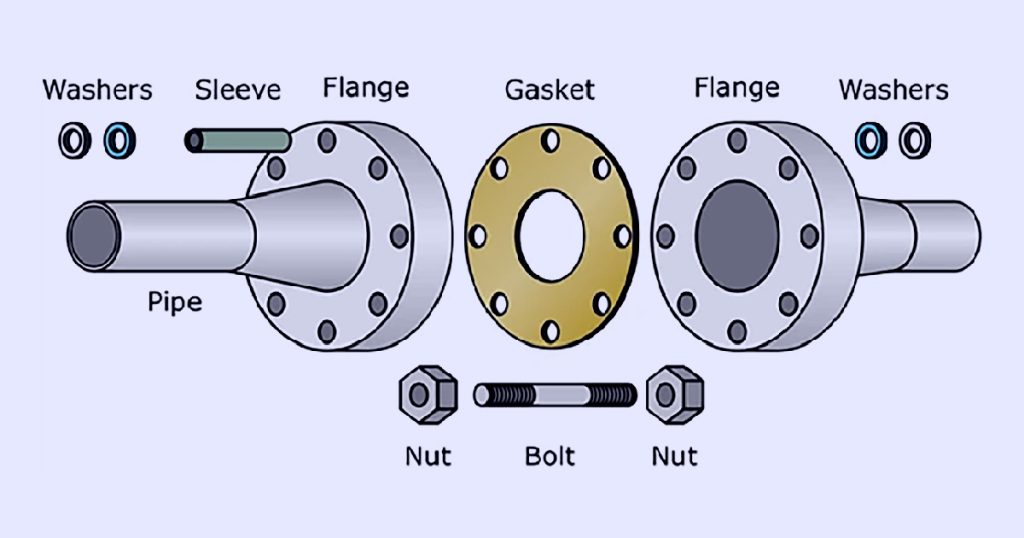

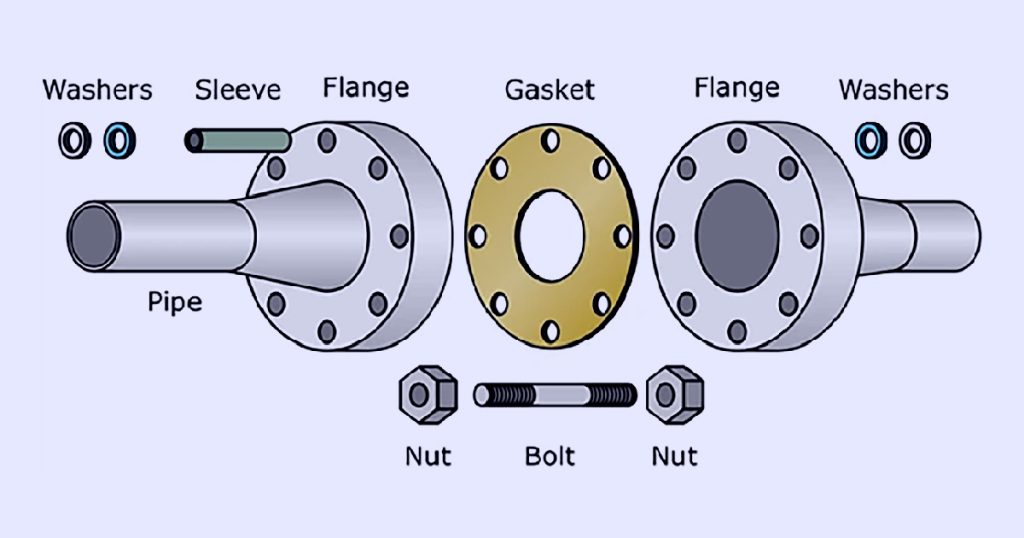

Installation

Preparation:

Ensure there is no presence of debris, oil or dirt present on the surface of the mating flanges to avoid any issues. Locate for presence of any sign of damage in flange surfaces and if found do not use it.

Alignment

Misalignment in the adjustment of the flanges may lead to development of leaks. Hence, ensure the proper alignment of flanges to avoid stress. Further, make use of alignment tools which can help to make accurate fittings.

Gasket installation

Make use of the correct size of flange gasket. Further, you can check materials like soft metal gaskets or PTFE which give a perfect fit. Place the gasket in the center to distribute the pressure between systems.

Bolt tightening

Make the bolt tightening process in a cross pattern to ensure an even distribution of pressure on the system. Apply the torque value as per specified value in the manufacturer list. Remember that over tightening or under tightening can lead to failure in the sealing of the gasket.

Sealing

Make use of compatible thread sealant which could tolerate the fluid pressure on the system.

Maintenance

You need to make regular inspections to check for any sign of damage or leaks.

Clean surfaces properly to avoid any sign of corrosion or damage.

Every time re-tighten the bolts if they get loosened up. Don’t go for over tightening which might lead to failure of connection due to increased pressure.

Make use of the protective coatings or cathodic protection to prevent corrosion in the system.

If you find any type of worn in parts of flanges then address immediate replacement.

Conclusion

SS flanges are mostly used in different industries due to its feature to provide the secure sealing in areas having high pressure and temperature where corrosivity is a major issue. These are available in various types for specific types of use in accordance with the need for the applied area. It provides great features like versatility, durability etc which makes SS flanges an ideal choice for different industries. It is very easy to install and maintain the connection for long term services. Following the best practices to install the flanges can enjoy the secured and reliable connection in the piping system.