It is very important to choose the right quality of the flange to ensure the longevity and performance level of your piping system. Does your mind opting to choose for the spectacle blind flange? Is it worth considering and installing? Well! To know the answer, read out further in this blog where you can understand utter detail about spectacle blind flange. You can know here in depth about versatility of spectacle blind flange which can become a solution to all your needs of application.

What is Spectacle Blind flange?

Spectacle blind flange is widely used in sealing between two connecting parts and also in supporting them. It is basically a type of safety device. It is installed in the area for the purpose of isolation of a particular part for maintenance, repair or testing. The design of the spectacle blind flange resembles the spectacle and hence named so. The design consists of an upper part which is called spectacle blinds along with two discs. These discs are generally mounted on each other which could get easily separated or bolted up together. The lower part possesses a ring like structure which fits well with the opening portion of the first component making it suitable and reliable for sealing in between both pipes.

Spectacle blind flanges are peculiarly used in the system facing high risk of explosions. It is because spectacle blind flanges are able to withstand any pressure build up in the system giving a safe environment. Even this particular type is applicable to areas facing medium pressure applications. It includes areas like steam service pipelines, pipe carrying fluids with higher temperature, in chemical plants and more.

Properties of Spectacle blind flange

Spectacle blind flange mainly works for the connection of two metal pieces together. Check out the following main properties of the spectacle blind flange as follows:

Design

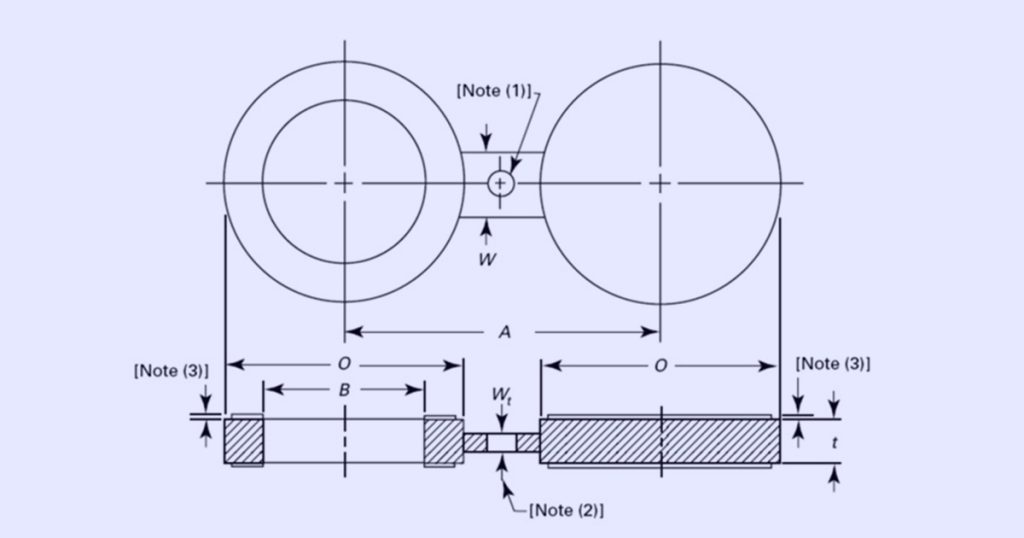

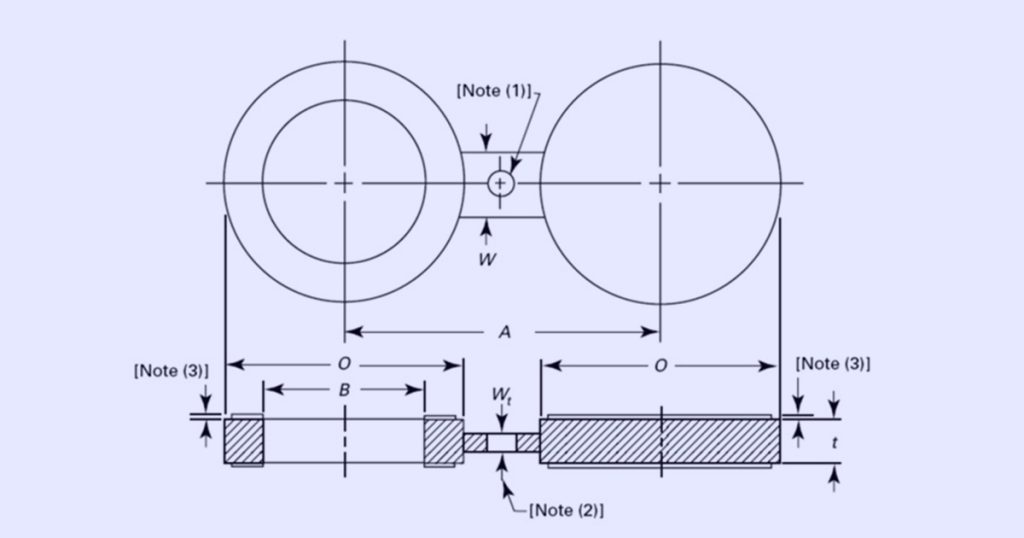

The first part consists of the solid disk which is mainly used to obstruct the flow in the pipe completely. The other part is of the ring which is called specter which allows a smooth flow of the fluid whenever needed. It is a type of single piece made with metal having a shape of figure eight.

Material

Spectacle blind flanges are generally made from different materials like stainless steel, carbon steel, alloy steel and more. The selection of the material is done on the basis of the tolerance in temperature and pressure when needed.

Size and standard

Spectacle blind flanges are available in the market offering different sizes from small to large dimensions. These are manufactured with following industrial standards like ASME, API or ANSI etc.

Installation

Spectacle blind flanges are installed in between the piping system to isolate or separate the particular area with another. These are easily rotated on open and close positions in design when bolts are tightened or loosen up accordingly.

Application

The basic application of the spectacle blind flange is to isolate the piping system from remaining to achieve the purpose of shutdowns, repairs or testing. Typically these are applied in areas facing high temperature and pressure conditions. It mainly includes petrochemical plants, refineries, gas pipelines and more.

Functionality

The closed site present in the design of the spectacle blind flange completely stops the flow of fluid in the pipeline. However, the open side makes smooth flow of fluid again whenever needed. It is very easy to flip the spectacle blind flange based on the operational requirement without making any disassembly of the flanges again and again.

Safety

It helps in providing the easy visibility for the flow status of fluid ensuring a safe operation and maintaining the piping system. Spectacle blind flanges totally prevent the accidents of sudden opening of the pressurized isolated valves.

Corrosion resistance

Choose a preferable corrosion resistance material of the spectacle blind flange. It will indeed help in corrosion resistance in harsh environments.

Application of Spectacle blind flange

Spectacle blind flanges are widely used as pressure retaining devices for easy isolation of a particular area from another. Due to this feature, spectacle blind flange is applicable in many different industries as follows:

Oil and gas industry

Oil and gas industries require frequent isolation of the piping system for varied purposes like maintenance, testing, repairs and more. It is very crucial to prevent leaks in these systems which is achieved with installation of spectacle blind flanges.

Chemical and petrochemical industries

These industries mostly need to deal with corrosive chemicals. Hence, spectacle blind flange is installed which is helpful in preventing leaks in the system.

Power generation

Steam and boiler machines need isolation and enhanced sealing for preventing hot steam or water leakage in the system which is achieved with spectacle blind flange.

Pharmaceutical industries

Pharmaceutical industries have higher demand for the sterilized environment to prevent any sort of contamination. Hence, spectacle blind flanges are installed here to maintain a sterile environment even during repairs, maintenance and cleaning.

Marine and ship building

Spectacle blind flanges in marine and shipbuilding industries are used to seal the vessel containing fuel, water and other essential fluids.

Water treatment plants

In water treatment plants, spectacle blind flanges are typically used to isolate the piping system for replacement, maintenance, repair, testing etc.

Benefits of Spectacle Blind flanges

Spectacle blind flanges are used in different piping system due to its several benefits which are as follows:

Positive shut off

Spectacle blind flanges are good enough to provide a complete sealing of the pipe giving a positive shut off of fluid. Once installed it doesn’t leave any chances of leakage.

Safety

These flanges are a reliable and safe option when it comes to physically blocking the flow of fluid. This blockage is most important during maintenance, isolation, repairs etc to avoid any accidental leaks.

Visual confirmation

The design of the spectacle blind flange allows for the easy type of visual confirmation. It is really easy to switch up between solid and open parts without need for disassembly of pipelines. Hence, it gives a clear visible confirmation about the status of the pipeline.

Ease of use

Spectacle blind flanges are very easy for installation and detach which doesn’t require a complex application process. Thus, it is proven more efficient and used widely in industries.

Durability

The materials used in spectacle blind flanges like stainless steel, carbon steel, alloy steel etc makes it more durable. Due to such material spectacle blind flanges have properties of high pressure, corrosion resistance and tolerance for high pressure or temperature.

Versatility

Spectacle blind flanges are versatile in nature due to its use in various industries. It includes chemical processing, power generation, oil and gas industries etc. The flange is typically used here for flow control or isolation in the piping system.

Cost-effective

Once after installation it doesn’t demand for frequent disassembly which ultimately reduces downtime of the system. Therefore, it proves to be a cost effective option for industrial piping systems.

How to install spectacle blind flange?

Installation of the spectacle blind flange needs to follow up with several different steps. Check out these for perfect installation of spectacle blind flange.

Tools and materials essential for installation

- Gasket

- Bolts and nuts

- Spectacle blind flange

- Lubricants used for bolts

- Torque wrench

- Safety equipments like helmet, gloves and eye protection spectacles

Steps for installation of spectacle blind flange

Safety precautions

- Ensure that at time of installation, the system is totally depressurized and drained out properly.

- Lockout and tag out for systems which help in prevention of any type of accidental startups.

- Wear up all safety materials like gloves, spectacles and more.

Prepare the spectacle blind

- Spectacle blind flanges consist of two different designs, The one comes as the solid which is typically meant for blocking the flow of the system. The other part is the open part which allows the proper flow of fluid whenever required. But among both ensure you have the preferable right part for installation.

- Clean up the spectacle blind flange properly to remove any sort of debris on the surface.

Align the flanges

- Loosen up all bolts of the flange where it is needed to be installed between the pipe.

- Apart the flanges a bit and quickly insert the spectacle blind in between them. If needed you can use a spreader for creation of space in between the flanges.

- Don’t try to make the forceful insertion of the spectacle blind in between flanges. It might increase the chances of flange damage in this process.

Insert the spectacle blind

- Install the spectacle blind flange in between of the flange which joins two different parts of the piping system. If you need to obstruct the flow of the system then prefer to insert the solid part. Whereas you need to adjust the open side of the spectacle blind to get continuous flow of fluid.

- Install the set up in such a way that holes of the spectacle blind and flanges align with each other properly.

Installation of gasket if needed

- In some of the cases it is needed to install the additional gasket outside of the spectacle blind for sealing of the system.

- Place the gasket in the set up before bolting up the spectacle blind in position.

Tighten the bolts

- Try to reinsert the bolts into flanges. Tighten up the bolts slowly making the criss cross pattern. This process will ensure the proper distribution of the pressure on flange faces.

- If it is needed to use the torque wrench then follow the manufacturer list to properly tighten the bolts.

Final inspection

- Once after installation, check the proper connection, tightening and even sealing of the system.

- Verify proper orientation in position of the spectacle blind depending on the need for either blocking or continuing the flow of the system.

Testing

- For testing, start to pressurize the system slowly and check for any sign of leaks or damage in the seal.

- If essential, try to make adjustments with bolts to get a secure fit.

Further, it is essential to make regular checks on the condition of the spectacle blind flange sealing, bolts and gaskets. All of these will ensure the safe operation of the piping system.

Conclusion

Spectacle blind flanges are proven versatile and reliable solutions for industries with need of isolating pipelines. It is important to understand the purpose, properties, installation process etc to get maximum benefits. Due to its versatile use, spectacle blind flange is applied in many of the industries in a wider range. There are noteworthy benefits of the spectacle blind flange once after installation. Even the process of installation doesn’t land up with complexities. Instead the simple but effective design of the flange makes the process of installation easier.

FAQs

What is the purpose of spectacle blind flange?

The main purpose of the spectacle blind flange is to block off the flow of fluid or gas in the pipeline. This is generally required for maintenance, repairs, cleaning, testing and more.

What is the difference between spectacle blind flange and spacer?

Spacers are typically used for preventing damage or corrosion on pipe ends especially during downtime of the system. But unlike spectacle blind flange, spacers are not efficient to completely block the flow of fluid rather it just helps in providing physical separation.

Do spectacle blind flanges need the use of a gasket during installation?

Yes, spectacle blind flanges are the design of the single metal piece which is used to fit between the flange that connects two pipes together. Therefore, it needs an extra gasket during the installation process.

Why is it given the name as spectacle blind flange?

The design of this flange is similar to the figure eight which gives the resemblance with spectacles. Thus, it is named as spectacle blind flange.

Is welding required during installation of spectacle blind flange?

No, spectacle blind flanges don’t demand any welding process during installation. Simply align the holes of flanges and bolt it together.