RF and RTJ flanges are one among the famous flange types used in industrial applications for various purposes of connecting the pipe together. These two particular flanges are widely opted in industries due to its special feature. Hence, it is important to select appropriate flange type industries like water and sewage, oil and gas, petrochemicals and more. Explore the exact meaning of RF and RTJ flanges and also their point of differentiation on the basis of various factors. It mainly includes temperature and pressure variation, surface design, installation, commissioning, gaskets, price, surface elevation and lots more.

What are RF flanges?

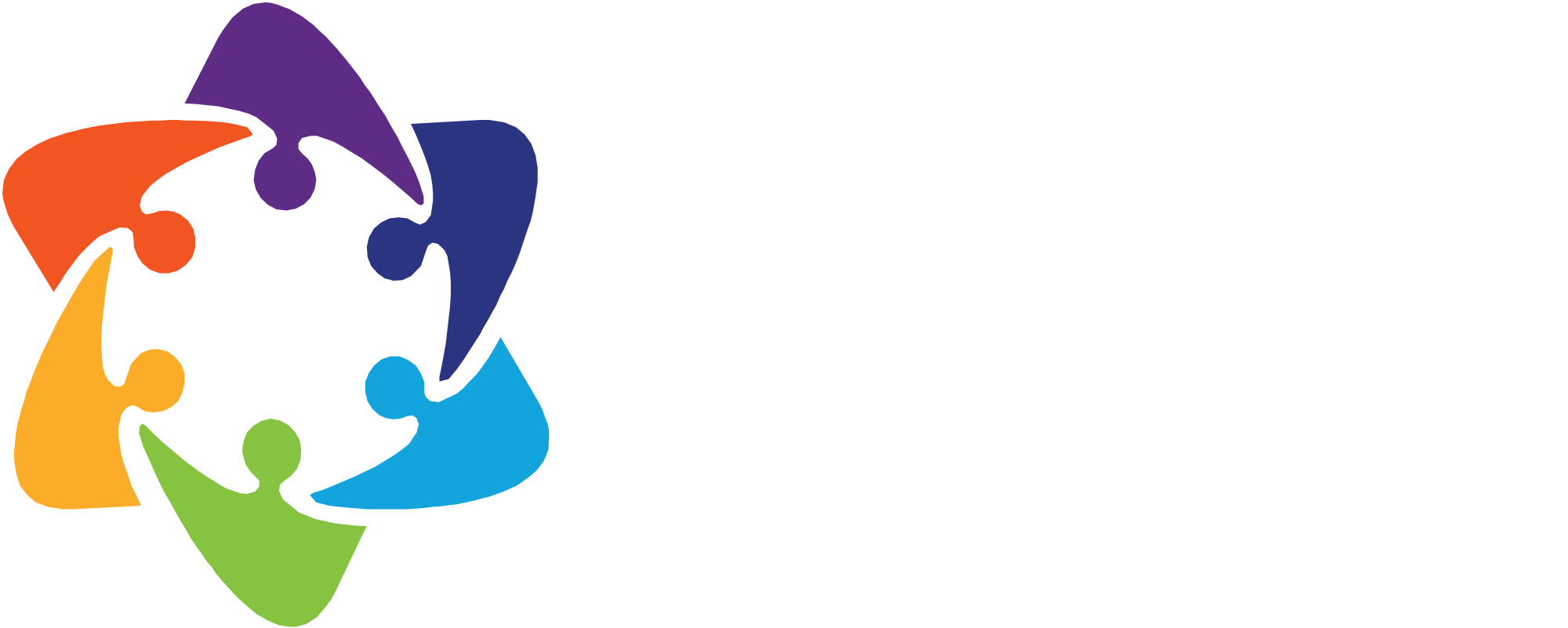

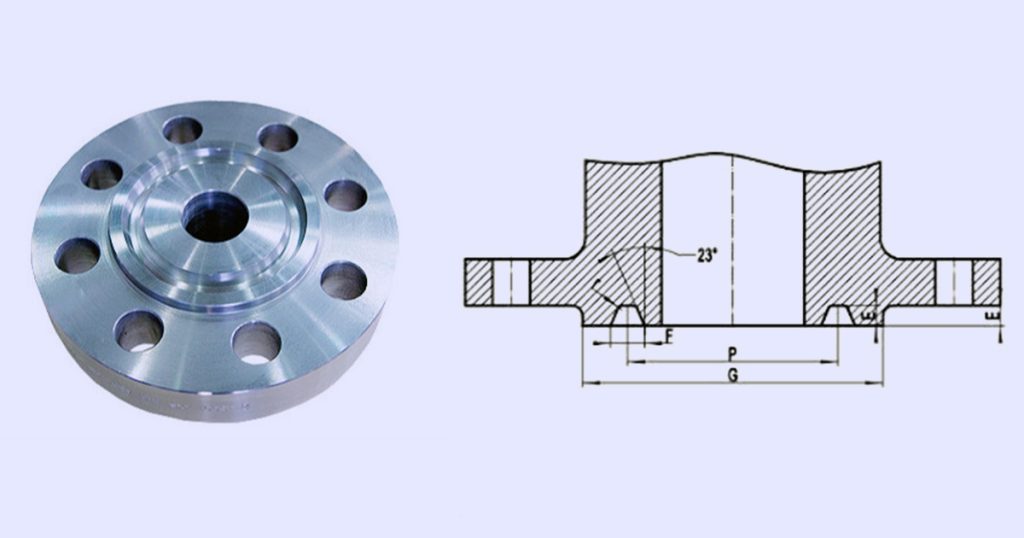

The term “Raised flanges” denotes the raised area present in the center of design of the flange where a gasket is fitted to get enhanced sealing. This design helps in reducing the stress and pressure with concentrating it on a smaller area for better sealing. This setup will allow a secured connection between two flanges. The RF flanges are preferable to use in areas facing medium to high pressure in the system. These are mostly applicable in oil and gas systems, power generation plants, chemical processing industries etc for getting a leak proof system.

What are RTJ flanges?

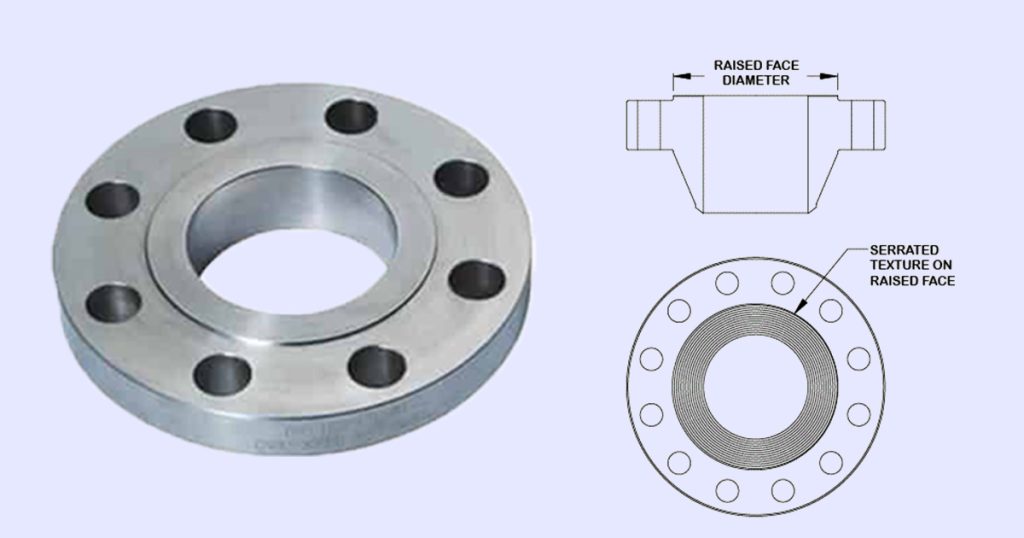

Ring type joint flanges are such types of flanges which have specific design to sustain high pressure and temperature areas. It helps in establishing a strong, leak-proof seal for a better type of system. There is a metal gasket which accommodates into a machine groove present on the surface of the flange. When flange and gasket are bolted together, the compression from flange to gasket creates a tight sealing which is resistant to leakage. These are designed to serve the secure sealing in systems facing extreme high pressure and temperature conditions. In industries like petrochemical, offshore plants, oil and gas have wider use of RTJ flanges.

Types of flange faces

- Flat face

- Lap joint flange

- Male and female

- Threaded flange

- Weld neck flanges

- Blind flange

- Socket weld flange

- Tongue and groove flange

- Orifice flanges

- Expander flanges

- Slip on flange

The difference between RF and RTJ flanges and other flange face types

Surface design

RF flanges

RF flanges have raised surfaces around its central bore portion. This raised face is typically used in the system to get a tighter connection with the gasket. Due to this design the entire pressure of the system gets distributed along the surface which ultimately helps in protecting the seal.

RTJ flanges

RTJ flanges have a specific mating surface in their design. This surface mating surface has a specific conical and ring shaped structure. These structures when mated together help in creating a tight and leak proof connection in the piping system.

Other flange face types

Most of the flange face possess the flat surface for appropriate sealing after placing appropriate gasket in between the connection.

Thickness

RF flanges

RF flanges are thinner as compared to RTJ flanges. The thickness of the flange is decided according to ASME or ANSI standards.

RTJ flange

RTJ flanges have more thickness as compared to RF flanges. The thickness is increased due to the presence of higher quality bolts and metal nuts. These bolts and nuts require a thicker surface to provide a leak free connection with enhanced sealing. This thickness is basically decided according to standards like API, ASME or ANSI etc.

Other flange face types

The thickness of most of the flange face varies according to their point of application. For instance the purpose of blind flange face is to obstruct the flow in the piping system. Hence, its thickness is adjusted as per the requirement at application area.

Pressure and temperature

RF flanges

These are specifically used in areas with moderate pressure and temperature conditions.

RTJ flanges

These are typically applied in industrial piping systems having high temperature and pressure conditions.

Other flange face types

There are many of the flange face used accordingly in both condition as per their design. Flat face flanges are applicable in low pressure areas whereas Tongue and Groove flanges with Male and Female flanges in high pressure and temperature conditions.

Installation

RF flanges

It is very easy to install the RF flanges because it only needs the perfect alignment between raised face and gasket surface. After this mating, RF flanges are attached with pipe to get a secured sealing.

RTJ flanges

Installation procedure of the RTJ flanges requires much precision. The metal ring present in the design needs perfect alignment with the flange surface to create tight and leak proof connections.

Gasket

RF flanges

The gasket of the RF flanges are specifically made with flat or grooved shape. These are composed of materials like graphite, PTFE etc.

RTJ flanges

RTJ flanges have the gasket which fits tightly with arrangement in design. The connecting ring helps for careful position of the gasket and flange. It helps in making a secured and leak proof connection in the system.

Other flange face types

There is essentially need for the gasket to place between the groove to secure a seal in piping system.

The height of the surface elevation

RF flanges

The height of the surface elevation in RF flanges is decided according to standards like ASME or ANSI or DIN. But both of these might get different in between RF and RTJ flanges. In general, the height of the ASME flanges varies from 2mm to 7mm.

RTJ flanges

Height of surface elevation in RTJ flanges is measured according to international standards like ASME, DIN and more. The height is much higher of the front projection in RTJ flanges as compared with RF flanges.

Other flange face types

Most of the flange faces have flat surface except for few with unique design like Tongue and groove flange and more.

Price

RF flanges

RF flanges are a bit lesser in price as compared with RTJ flanges. These are generally used in the environment which faces lesser pressure and temperature conditions.

RTJ flanges

Mainly the price of the RTJ flanges varies according to their temperature, pressure, material and size. RTJ flanges are more expensive as compared with RF flanges. These are mostly applicable in high pressure and temperature conditions.

Other flange face types

The price of the flange face types varies with size, material, grade and more. But these are comparatively less expensive as compared with RF and RTJ flanges.

Sealing surface

RF flanges

Raised face flange has a presence of bore around the flange. The flange helps in providing a seat for the gasket to get adjusted in between the face. These are most widely used with gaskets having flat, soft or spiral wound shapes.

RTJ flanges

There is presence of machine grooved structure in metal ring gasket which has oval or octagonal cross section which help in fitting well. This design leads to formation of tight metal to metal sealing in the system. These are made for high temperature and pressure applications.

Other flange face types

Every type of the flange face has their unique design and so comes sealing surface. Flanges like Tongue and Groove has specialized groove made to fit well at point of pipe connection.

Application

RF flanges

These are applicable in the low pressure pipe area. It is typically used in industries like chemical, oil and gas, water and more. RF flanges are suitable to use in a medium which does not face corrosive conditions or extreme pressure conditions.

RTJ flanges

These are mostly used in high pressure and temperature areas like in petrochemicals, oil and gas and more. RTJ flanges can also tolerate corrosive environments and make a leak proof system to tolerate harsh conditions.

Other flange face types

Flat flange are applied in brittle materials. However, Threaded flanges, slip on flanges, lap joint flanges are applicable to low to moderate level.

Conclusion

Each type of the flange face available has their own set of design for meeting specific application demands. The main difference between RF and RTJ flanges and other flange face lies in their sealing mechanism, appearance, installation, requirement of maintenance and more. RF flanges typically used in systems with low or medium pressure and temperature areas. However, the innovative design of RTJ flanges helps its installation be suitable in high pressure and temperature conditions. RTJ flange demands more precision during alignment between the flange and gasket surface to get reliable sealing. It is very crucial to understand the basic difference between RTJ, RF and other types of flanges. All of this information will help you to make a right choice in between RF and RTJ flanges to ensure a smooth, safe and reliable operation of your piping system.

FAQs

What is the main difference between RF and RTJ flanges?

RF flanges are applicable in low to moderate pressure and temperature areas. However, RTJ flanges are typically made to use in extreme temperature and pressure conditions.

What are different types of flange faces?

Mostly there are three types of flange faces named as ring type joint flange, plain or flat face and raised face flanges.

What are the different types of gaskets used in increasing the sealing capacity of the flange face?

Primarily there are three types of flange gaskets used for enhancing sealing capacity named as non-metallic, metal and semi-metallic.

Which are the basic standards used in selection of RF, RTJ and other types of flange faces?

The selection and manufacturing of the flange faces are done in accordance with standards like ASTM, DIN, ANSI B16.5, ANSI B16.47 and more.

Is it possible to connect RF and RTJ flanges?

No, it is not possible to connect RF and RTJ flanges together. It is because RF and RTJ flanges are much different from each other in design , gasket fittings, sealing mechanism, pressure and temperature ratings etc.