You would definitely understand the importance of the flange in industry to gain connection in the piping system. Further, you have come across the wide use of Ring type joints and raised flanges. But how these two differ from each other. Well! The difference is pretty simple between the two of them. You need to select the one based on the application of your area and need of the joint.

Sit aside and explore detailed differentiation between RF and RTJ flanges. Both of these are designed with specific aims in industrial use. Each of them has some advantages and limitations to consider. Keep all of the mentioned criteria in the checklist and it will help you to choose the right flange type for your application.

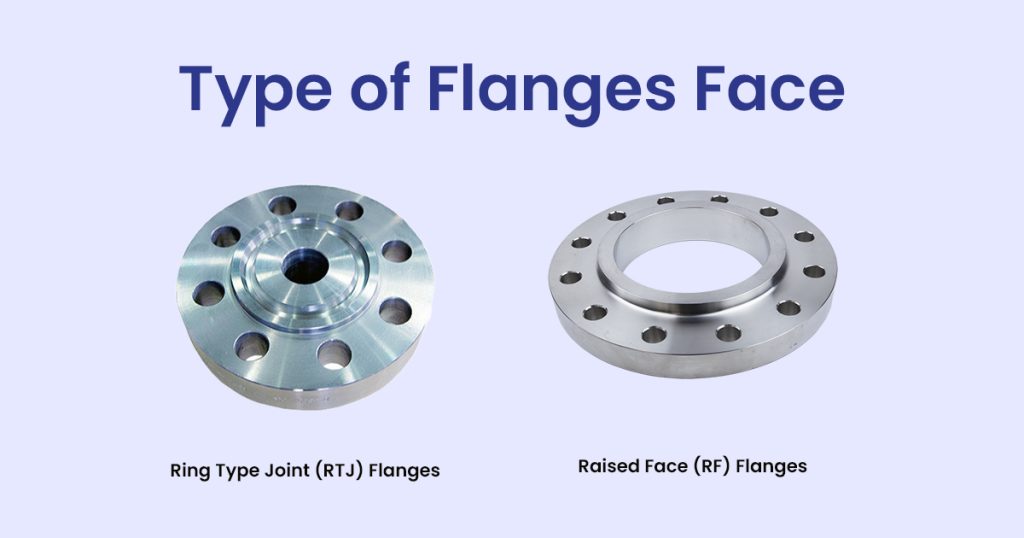

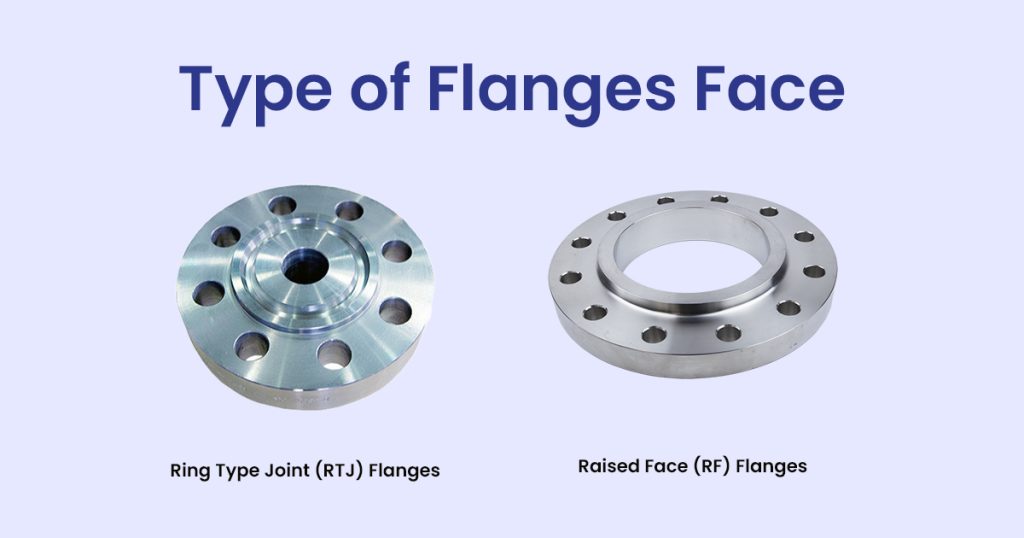

Raised Face (RF) Flanges

The design of this flange has a slight raise on the gasket surface above the bolting circle. Hence, it is termed as raised face flange. These raise face will have serrations for gasket seals. It comes with majorly two types of serrations. Continuous serrations are a spiral on the face of the flange, from the outside edge to the inner bore, or to the center in the case of a blind flange. Concentric serrations are circular grooves spaced evenly across the entire face, like a bullseye. Due to this design it avails the to fit in with many types of gasket like one ranging from spiral, double jacketed till flat ring sheets. Also, you can go with a wide range of the gasket materials like flat cut, metallic and semi-metallic.

The main aim of the RF flanges is to focus the pressure on a smaller area to get the secured sealing. According to the ASME B16.5 standardization, RF flanges can follow a pressure class of range 150 to 300 with height of about 1.6mm. Further, increasing the pressure range to 400 to 2500 the height increases till 6.4mm. Typically these are available in 125 to 250 in Ra.

Raised face flange is the most common type applicable in plant application industries. Further, industries like chemical, farm, water treatment etc have found the wide use of RF flanges.

Advantages

Raised face flanges enable one to make a choice for wider range for gasket selection. It comes under a spiral wound to flat ring sheets.

A raised face flange design is considered the most accessible type. Thus, it becomes very easy to replace worn gaskets certainly.

The design of RF flanges helps to concentrate the pressure on the smaller gasket. Hence, it helps the flange seal handle the more pressure from the system.

You can find a better separation between the joints while connected through flanges.

Limitations

RF flanges require some rigid rules for application in the piping system.

Ring Type Joint (RTJ) Flanges

Ring type joint flanges are best for creating the metal to metal sealing with mating flange. Due to this design, it is especially applicable to areas facing high temperature and pressure. RTJ flanges have the presence of circular grooves which allows adjustment of metallic ring joint type gaskets.

The two mating RTJ flanges are bolted together with applied force along with a gasket placed inside. Due to applied force, the gasket deforms inside the joint creating a tighter metal to metal incredible sealing. There are available many gaskets in different styles and profiles which suit RTJ flanges. It includes styles like R, RX, BX and more.

Advantages

RTJ flanges offer a joining of metal to metal. Hence, it gives much stronger sealing which could withstand pressure, extreme temperature and corrosion due to hazardous chemical exposure.

If space created between the flange is a possible reason for failure of sealing? If yes, then you should definitely know this advantage of RTJ. It allows the tight fitting within grooves to avoid spaces.

Tighten the bolts correctly with the gasket and the job is done. Further, it could handle all compression with movements and vibrations.

Use the appropriate type of the gasket which can allow you to make a direct contact with the mating one to get a reliable sealing.

Limitation

These are not readily available in the market and hence prove a bit of a costlier option.

Comparative Analysis

Key difference

Raised face (RF) flanges

It has the feature of a small raised area around the circumference of the bore. Thus, it provides a larger surface area for the gasket to compress and make secured connections.

Gasket types like spiral, ring and full face are suitable here.

These are used preferably in the low pressure ratings.

Ring joint type (RTJ) flanges

It has a precise machined groove which allows a proper seat for metal gasket.

These are enough to provide the tight seal making an ideal choice for high pressure and temperature.

RTJ flanges are applicable in oil and gas industries for reliability with extreme conditions.

Pressure and temperature ranges

Raised face (RF) flanges

These are applicable for moderate pressure and temperature facing areas.

Pressure classes range from 150 to 2500 PSI.

The limits of temperature might vary depending upon the material used like carbon steel which can handle up to 750°F.

Ring joint type (RTJ) flanges

These are specially designed for high pressure and high temperature applications.

Pressure classes might go beyond 20,000 PSI or more.

Depending on the material selected RTJ flanges could withstand 1000°F and more.

Installation considerations

Raised face(RF) flanges

RF flanges are easy to install due the simple design and variety of options available with gasket.

These might require a precise measurement for proper alignment of the gasket to get secured sealing.

It is important to select a particular gasket selection and installation process for avoiding any leaks in the system.

Ring joint type (RTJ) flanges

RTJ flanges require the precision for installation of ring gasket in groove to get durable sealing.

Misalignment or improper measure can result in potential failure and inappropriate sealing.

The installation process requires skill and attention to each smaller detail to get a secure connection of RTJ flanges.

Maintenance considerations

Raised face(RF) flanges

It is easy to inspect and maintain the gasket making the process easy and straightforward.

Gaskets suitable for RF flanges are cheaper and easily available in the market.

Regular inspection for the gasket is important to maintain integrity of sealing in the piping system.

Ring joint type (RTJ) flanges

Maintenance needs necessary inspection of the ring groove for any sign of wear or damage.

Metal ring gaskets used here are durable but are proven expensive. Also, it demands for more time and efforts to make replacement,

RTJ flanges provide high reliability sealing to systems which obviously require thorough and frequent maintenance.

Selection Guide

Factors to consider when choosing between RF and RTJ flanges

There are several factors to consider when choosing between RF and RTJ flanges as follows

Temperature and pressure ratings

Raised face(RF) flanges

These are suitable for application with areas dealing with moderate levels of temperature and pressure. Therefore, it is installed in many industries like petrochemical, chemical and water treatment plants.

Ring joint type flanges

RTJ flanges are designed for the high pressure and temperature applications. These are applicable in oil and gas industries to deal with critical services.

Sealing mechanism

Raised face (RF) flange

Make use of the gasket placed in between the mating flanges. These types of the sealing might prove reliant but not as effective when compared with RTJ flanges.

Ring type joint (RTJ) flanges

Prefer the use of the gasket which easily fits into the machined groove present in the flange. This will be able to make out the tight sealing which is reliable enough to tolerate high pressure and temperature conditions.

Leakage prevention

Raised face(RF) flanges

These are enough to tolerate the low pressure conditions but cannot withstand the extreme temperature conditions.

Ring type joint (RTJ) flanges

This gives an incredible sealing performance ultimately giving minimal risk of the leakage. Even the sealing is able to tolerate the severe conditions of temperature and pressure.

Installation and maintenance

Raised face (RF) flange

These are very easy to install and align together. These are best for making out the surface finish and flatness.

Ring type joint (RTJ) flange

These require the expertise to install and precision for alignment of flanges. This might give you a challenge to maintain and give an exact fitting of the ring gasket.

Cost

Raised face (RF) flanges

These are less costly as compared with RTJ flanges.

Ring type joint (RTJ) flange

These are higher in cost due to the requirement of the machine’s precise work. Also, the price of ring gaskets contributes to overall expense.

Application suitability

Raised face( RF) flange

It is suitable to apply on the area which doesn’t require to tolerate the extreme conditions of temperature and pressure.

Ring type joint (RTJ) flange b

RTJ flanges are proven ideal in industrial applications like refineries, petrochemical plants, thermal power plants , steam turbines and more. Here it offers high reliability on the sealing of the system.

Industrial standards and certification

ASME/ ANSI B16.5 – these are applied to the flanges and flanged fittings.

API 6A: Specifications will get for RTJ flanges

API 6D: it provides specification for pipelines, valves and even flanges.

EN 1092-1: it is applicable for the European countries

ISO 7005-1: international standard for the standardization and certificate.

After considering all of these factors you can make informed decisions based on the requirements of the application. Priorities reliability, cost and safety for your piping system of flanges.

Conclusion

Raised face flanges and ring joint type flanges are both important from the industrial point of view. The difference between two lies at design and point of application at particular temperature and pressure conditions. Further, you can prefer to compare the factors before moving further with one particular. You need to consider the reliability, point of application in terms of pressure and temperature conditions, cost and more. Once you get clear with these points it becomes easy to choose one between RF and RTJ flanges.

FAQ’s

What are the common gasket materials used with RF and RTJ flanges?

The common gasket materials used in RF flanges are natural and synthetic rubber , compressed non asbestos fibre, PTFE , flexible graphite abd sometimes metal gasket while for RTJ flanges soft iron, stainless steel, low carbon steel, alloy steel, copper alloy, nickel alloy and more.

How do you properly install and torque RTJ and RF flanges to prevent leaks?

The RTJ and RF flanges have a presence of gasket between the two mating flanges. In the installation process, these are bolted together applying appropriate force. This leads to compression of the gasket in between flanges creating a secured sealing. This metal to metal sealing is enough to prevent leaks in the system.

What are the cost differences between RF and RTJ flanges and their long-term maintenance implications?

RF flanges are comparatively cheaper, easy to maintain and ideal for low pressure application. Whereas, RTJ flanges provide long term reliability proving a bit expensive and demanding for frequent maintenance.

Are there any specific standards or certifications required for RF and RTJ flanges in certain industries?

Yes, you need to consider the standards like ASME/ANSI B16.5, API 60, API 6D, EN 1092, ISO 7005-1 etc.

What are the potential failure modes for RF and RTJ flanges, and how can they be mitigated?

The potential failure for the system might result if there is no periodic maintenance and inspection. It requires replacement of the wear of damaged parts of the gasket and flanges which proves a possible way to mitigate the failures.