Are you planning for a piping system installation? If yes, then it is important to select the pipe flange and other fitting which meets the high quality and standards. This criteria directly depends on the flange manufacturer you choose. It becomes crucial to select a good quality of the flange in your piping system to ensure its longevity after installation.

The quality of the flange directly influences the safety and efficiency to carry out any process in the industry. Hence, it is very important to choose the right flange manufacturer. To feel assured about your decision you need to refer to this blog to understand the consideration while selecting a flange manufacturer.

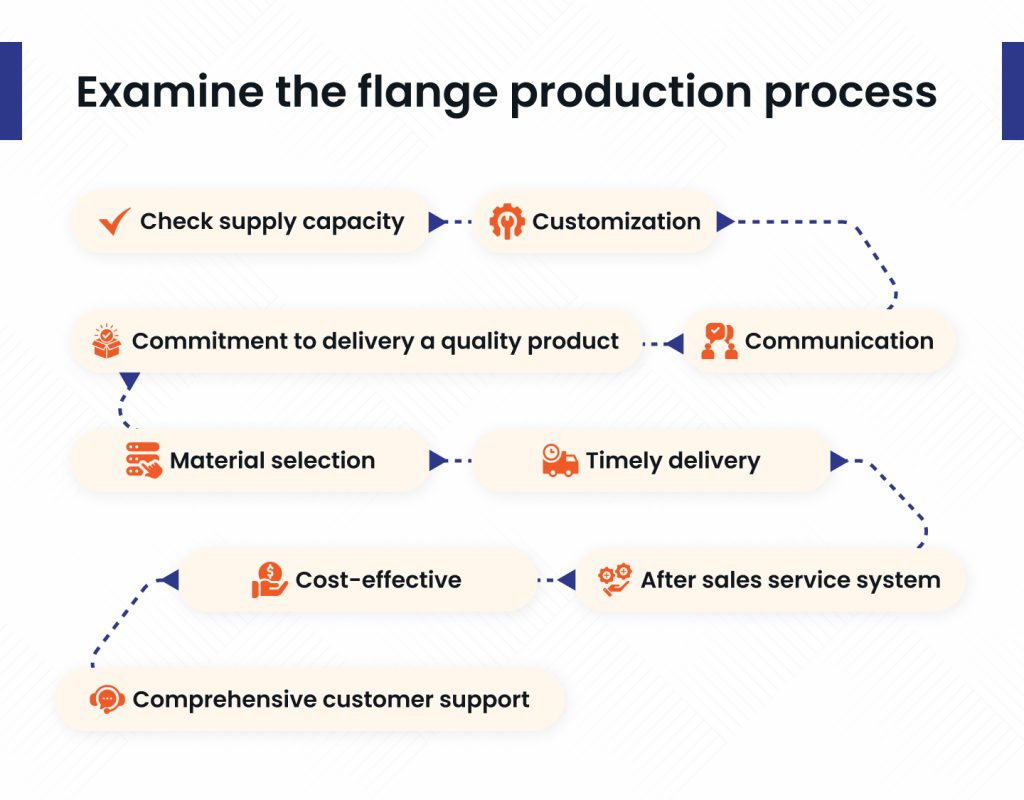

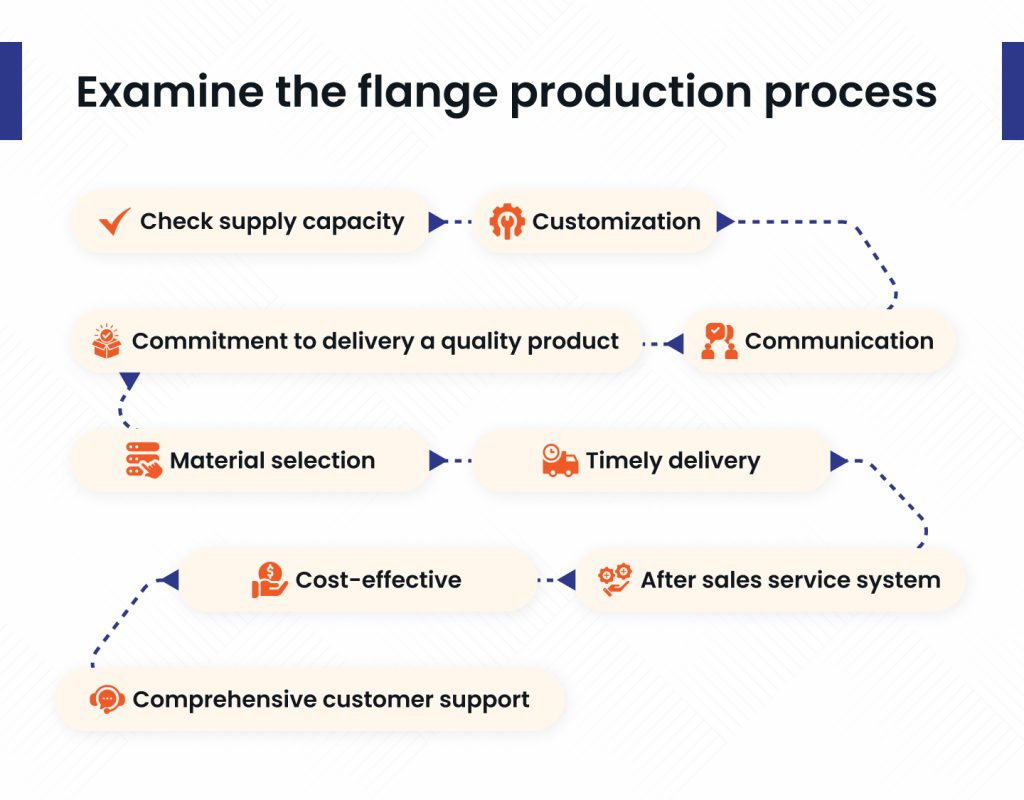

Examine the flange production process

Very first and important step is to directly examine the process of flange production of selected manufacturers to ensure the quality. Here, you should verify if the production of the flange meets the particular standards and requirements for your area of application. Further, you can even ask the flange manufacturer to make changes accordingly to meet your work process.

Don’t forget to verify the quality control system of the flange manufacturer. It includes checking of various factors like thickness gauges, liquid penetrant testing, hardness testers and more. Ensure that the flange manufacturer makes a robust inspection of the product before and after shipping.

Check supply capacity

One thing which puts in great effort is to refer to multiple manufacturers in order to get different parts. It will indeed become an exhausting as well as time consuming process. There is always a risk of miscommunication internally between the suppliers which can ruin your project. So what is the solution to avoid this tedious situation?

Here, whenever you sit to speak with any flange manufacturer, look upon the quality of the products that they supply. Check what kind of products the manufacturer serves like long weld neck, forged steel fittings etc. In short, the more products they offer the less you need to search for different parts from other manufacturers. Try to seek for one stop solution in form of a flange manufacturer which possesses a higher supply capacity of products.

Customization

It is very obvious that your project might have some unique requirement which is not readily fulfilled with pipe fittings available in the market. You might frequently face the challenging demand for your area of application which certainly requires customization. Seek for the flange manufacturer who is flexible with providing custom flanges and other fitting products.

You would definitely come across the need of many customized fitting in your area. It mainly includes flow nozzles, high yield fittings, weld saddles and other wellhead components. Hence, select a top-notch flange manufacturer who possesses capabilities to make customization according to your requirement. The manufacturer should have willingness to tailor the product according to your need which might come with materials, dimension or rather special coatings.

Communication

Clear and transparent communication is the base of success regardless of any business. It helps to establish a strong relation between the customer and supplier. If your manufacturer sits and answers all of your questions satisfactorily then consider it as a green flag. The best way for the identity among your shortlisted flange manufacturer is to make communication through email or call. An efficient manufacturer will indeed reply to your mails or respond to phone calls as soon as possible.

Commitment to delivery a quality product

Choose the flange manufacturer who indeed follows the standards to maintain top-notch quality like AST, ISO or ANSI. The product which the manufacturer delivers should meet the quality standards. You should definitely give a priority to a particular manufacturer among all shortlisted who believes in delivering quality products.

Material selection

Flanges are available in the market with various materials which are designed to meet the specific environmental conditions and different application areas. Select a flange manufacturer who offers a variety of material ranging from stainless steel till carbon steel and more. It will ensure the flange installed in your system could withstand harsh conditions and remain functional for a longer duration of project cycle.

Timely delivery

In this fast paced world time is equal to money. An efficient flange manufacturer should be able to produce the quality product and even deliver it before the deadline of the contract. Delay in the delivery can ruin your future schedules and might also increase other unnecessary expenditures. Hence, choose a flange manufacturer who follows the discipline and punctuality towards their work.

After sales service system

It is very important to choose the manufacturer who provides an after sales service system. The system includes following credentials:

Provide spare parts of the flanges for free or at reasonable rates as compared with market price.

Free and scheduled technical services like installation, training and maintenance for a particular time duration.

A flange manufacturer should appoint a team of skilled engineers who can approach you to solve the technical problems immediately.

Offer a warranty on the performance and quality of the product of a certain period.

Cost-effective

Check on the price tag that the manufacturer puts on the product which should sound reasonable as well as competitive with the market. Some of the flange manufacturers focus on the production using stainless steel and alloys whereas some prefer to use different polymers or copper. Therefore, you need to compare the price of a product with another manufacturer keeping the same point of comparison like size, materials and quality.

Check for the gaps present between each flange type or its different product categories. For example, a stainless steel flange meets a budget friendly stock fitting than it lies in the budget friendly range. However, if the demand goes for the customization then the cost might increase considerably.

Comprehensive customer support

An efficient and reputable flange manufacturer doesn’t end up their services till delivering the quality product but it indeed extends till providing satisfactory customer support. They need to have a efficient support which could deal with queries related to pre-sales as well as after sale services. Select a flange manufacturer which should have team who can navigate your issues in quick and responsive way.

Conclusion

In a scenario where you cannot compromise over things, prioritizing quality of product is foremost consideration. Look out for the flange manufacturer who works on the esteemed standards set for the industries and delivers the same product within deadline. Select a manufacturer who can provide customization which ultimately indicates the versatility offered to you. A support team provided should help you from initial inquiries till any queries faced even after delivery services. Remember, selection of the right flange manufacturer is not just a provider but also a reflection for the operational excellence in your industry.

FAQs

Is there any specific certification essential to check when choosing for the manufacturer?

Yes, you have to check the certification from the manufacturer of materials especially. Further, you should check about the quality and compliance which manufacturer produces that should match with industrial standards.

How can you know about the reputation of a particular manufacturer in the market?

Very firstly check the online reviews, observe their track records of other previous projects and ask for references from the same clients to know their real reputation in the market.

What is essential to keep in mind when you do selection of the manufacturer?

There are various factors like after sales support, the number of references offered from the manufacturer, effective communication etc can help you to conclude a right decision of selecting a flange manufacturer. Also, make a quick review for reputation, experiences, certification, feature of customization, pricing etc.

How can the experience of the manufacturer affect the selection process?

It is important to check the experience of the flange manufacturer which could reflect many things. It includes quality products, handles the specification required for particular clients as well as ability to understand demands of industry.

What is the specific standard required to select a flange?

The production of the flange should follow specific standards like ANSI B16.5, ASME B16.5 and more.