Pipe flanges have great importance in the piping system. Despite this, there are many of the flange types whose work remain unaware to people. Among those the one is blind flange. What makes it work unique as compared to other types? Why is it called as blind flange? Blind flange might not prove much popular as compared to other types. Explore the detailed understanding for blind flanges, definition, types, application, maintenance, benefits etc.

What are Blind Flanges?

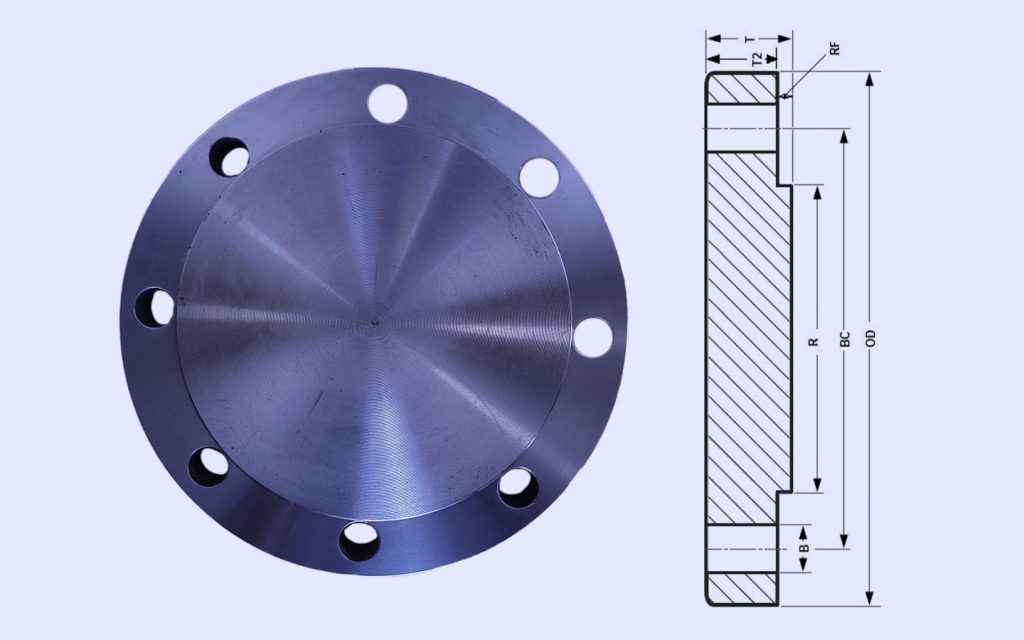

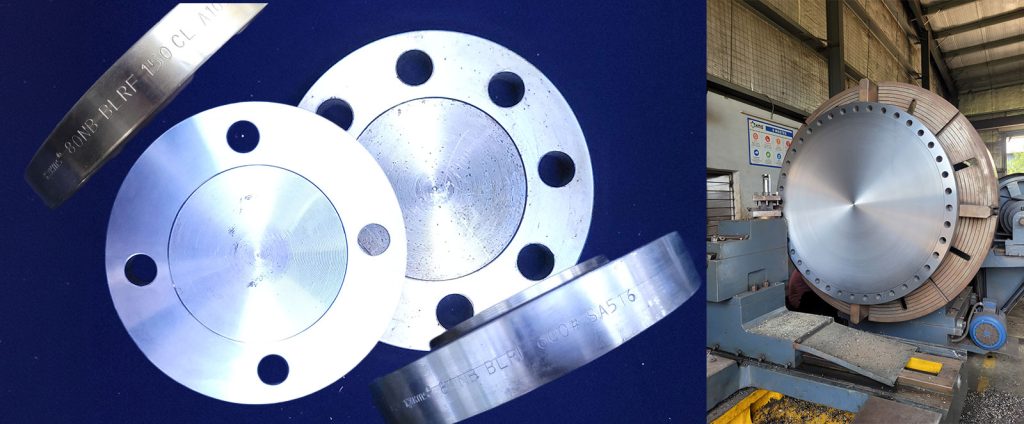

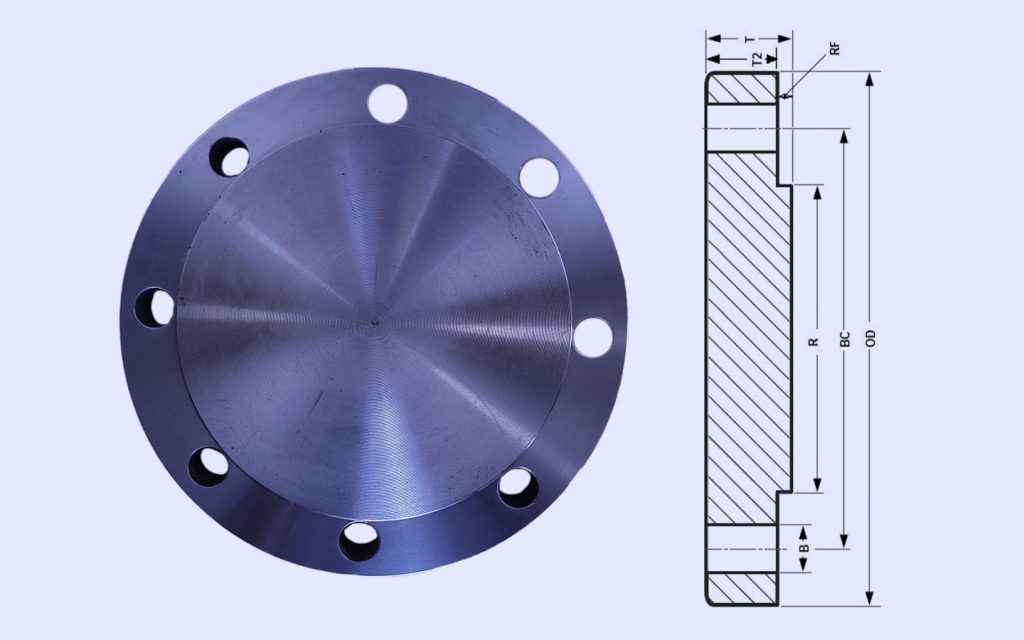

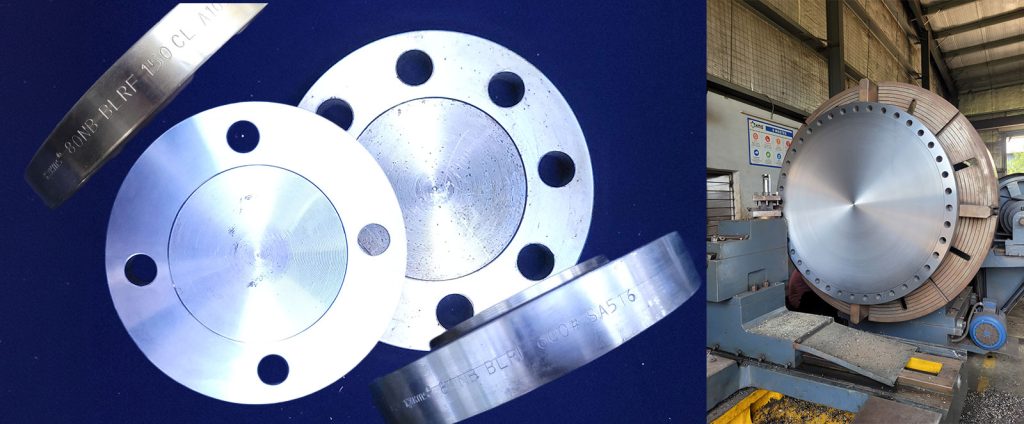

There are considered as the most unique part for the piping system. It is simple in function but important in closing the end of the pipe. Blind flange has a defined face for sealing the end of the pipe which appears like a solid, flat disc with bolts.

The primary and essential use of blind flange is to block or stop the flow of fluid or gas in the system for a certain period of time. It is needed to install when a pipe end needs separation from the rest of the system. This situation arises under repairs, maintenance and some other reasons. In short, blind flange is used to create a barrier in passage of any substance flowing via pipe.

There are not only proven great in functionality but also versatile. It is because of the availability of different diameter, pressure ratings and materials for various uses.

Installation of blind flange is very easy and straightforward. You just need to apply it at the open end of the pipe which needs closure temporarily. Further, bolt the holes present in its circumference and the job is done. The space between flange and pipe is filled with gasket to ensure leak proof sealing. Further, evenly tightening of bolts makes more secure sealing.

Types of Blind Flanges

Raised face blind flanges

It is named as raised face blind flange because of the presence of a raised ring around the flange. This creates a strong seal on the piping system when mated with another same type of flange.

Specifically it is applicable to high pressure areas. It is because the raised face increases the strength of sealing due to larger surface area.

Flat face blind flange contains a flat surface in the entire area of the disc. Due to this, it is used less often as compared with the raised and ring type of blind flange. It is because the flat surface provides lesser salability.

These are mainly applicable when need to seal the low pressure area.

Ring joint blind flanges

Ring joint blind flange has the presence of metal gasket to make a secure connection for sealing of the piping system. It has the potential to face the extreme conditions created in pipes with fluid flow.

Ring joint blind flange is particularly applied in high temperature and pressure areas to ensure effective sealing.

Applications of Blind Flanges

Oil and gas industry

Oil and gas industries need the frequent maintenance and cleaning of sections to ensure the uninterrupted flow of fluid and gas. There are used here to seal off the sections to terminate any leak possibilities. Even when need for the maintenance and repair blind flanges are applied to industries.

Chemical industry

There are employed in plants of the chemical industry to close the flow of pipelines. After this, proper processing of inspection, repair and maintenance is carried out. These all ensure the integrity of the system from leak.

Water industry

In the water industry different blind flange dimensions are used to isolate the system. It is mostly used at the time of cleaning of pumps, valves or pipelines. All of this will ensure the water quality and its efficiency.

Installation Best Practices

It is very crucial to carry out best practice of installation to ensure integrity and maintenance of the system. Follow this step by step guide to best practice of installation of blind flange.

Prepare the work area

Make sure to properly prepare the area with cleaning and set it free of any obstacles. Ensure to have all essential equipment readily available to avoid any hindrance in the installation process.

Inspect the flange

Look for any defects present in blind flange before actual installation like damage, corrosive or cracked areas. Also, verify the standards and certifications of flange used for specific applications.

Prepare the piping system

Firstly clean the pipe with removing any dirt, debris present in old gasket materials. Imperfections could affect the efficiency of sealing in a piping system with blind flange. Therefore, ensure the smooth surface of pipe before sealing.

Position of flange

Place the blind flange of suitable type at the end of the pipe and check for proper alignment of bolt holes. The flange should have a position perpendicular to the pipe which is considered the correct way of sealing.

Install gaskets

Pick up two similar mating flange faces and place the gasket in between to create a seal. The gasket should tolerate the temperature of the applied area and suit the fluid flowing through the pipe.

Insert bolts and nuts

Place the bolts in holes of blind flange and pipe in evenly spaced manner with proper alignment. Tighten the bolts to secure the position of the flange in the same place.

Tighten the bolts

Try to tighten the bolts using equipment like calibrated torque wrench in cress cross pattern slowly. This way you can ensure the proper tightening of the blind flange. Also, it reduces the chances of uneven pressure and distortion of the flange installed at the end of the pipe.

Check proper alignment

Once you finish with tightening of bolts, cross check the alignment of the flange placed perpendicular to the pipe. Fix the adjustment if required to get proper alignment.

Final inspection

Check for any damage, misalignment or leaks present in the blind flange after installation. Also, you can prefer to conduct a pressure test to know the level of integrity of sealing the pipe end.

Document installation

Prefer to maintain the record of installation process, torque values and inspection after getting results. This documentation practice is important to further maintenance and compliance of the piping system.

Maintenance and Inspection

Maintenance and inspection of installed blind flange is essential to have reliability of the piping system. Let’s check how to maintain and inspect the blind flange.

Regular visual maintenance

Look for any sign of corrosion, damage or leaks that persist in blind flange periodically. Also, check out any sign of rust, cracks, deformation etc. abnormalities present on the surface.

Check gaskets

Make proper inspection of materials to tolerate the wear, tear or compression properly. Prefer the replacement of gaskets if there is any sign of major damage or deformation in sealing of pipe.

Bolt tightness

Use the calibrated torque wrench to ensure the tightness of bolts and nuts on a regular basis. Make sure these are properly tightened to reduce accidents of leak or distortion in the system.

Sealing surface

Examine if there is any presence of scoring, erosion or pitting on the surface of blind flange. Smooth out imperfections persisted or replace the flange if needed to update the sealing of pipe.

Pressure testing

Regular inspection with pressure testing can help to detect any leaks present in the system. It will ensure the integrity of the system when actually applied at operation with fluid or gas flow in the system.

Corrosion protection

Use the corrosion resistant coatings or cathodic protection as part of corrosion protection measures on blind flange, It will help to prevent any deterioration and increase the longevity of the seal.

Documentation

Regularly document the repairs, replacements, inspections, maintenance activities in a detailed way. It will help to track the present condition of blind flange seals and also an idea for future maintenance.

Emergency response

Always prefer to have an emergency response to deal with accidents of failure or leakage in blind flange. Give the personnel proper training to make quick responses to effectively reduce downtime of the system.

Benefits of Using Blind Flanges

Leak prevention, pressure maintenance, ease of maintenance, etc.

Quickly make out the view for the benefits of using blind flanges.

Leak prevention

There are beneficial to make a secure seal which prevents anu leak in piping system. Hence, it is best proven for industries dealing with hazardous or toxic substances.

Convenience in maintenance

There are used to isolate the particular part of the pipe closing it temporarily. Further, maintenance for the other half of the system is proven effective.

Pressure maintenance

They can help to maintain the pressure on the system especially when ports get uplifted in the body.

Safety

While testing hazardous or toxic substances in industries, it is important to prevent leaks. This is achieved with use of blind flange to ensure safety from unpredicted accidents.

Easy installation

It is very easy to install the blind flange. You just need to place the gasket between the pipe end and blind flange. Then tighten the bolts and it’s done. It doesn’t need much expertise to use this particular flange type.

Versatility

There are available in different dimensions, size and materials. Hence, you can use its versatile nature to pick the best suitable measure for your requirement.

Cost effective

The maintenance needs much downtime to close the system. Blind flange can help the system to reduce downtime also in cost effective options.

Longevity

There are made with material which proves corrosion resistance as well as durable. Hence, it ensures the longevity of a system extending life span after installation.

Adaptability

There are enough to adapt in high pressure and temperature conditions. Therefore, it makes better adaptation to withstand environments.

Customization

You can find the customization in materials available in the blind flange. It includes carbon steel, stainless steel and more to customize according to need.

No flow restrictions

Blind flange doesn’t contain any bore. Hence, the installation will not interrupt the flow when not in usage.

Lower maintenance cost

They can help to minimize the requirement of frequent maintenance and repairs in the system.

Uniform stress distribution

The blind flange has a flat disc which on installation works to distribute the stress uniformly to avoid the chances of breakage due to pressure.

Conclusion

Recap of the importance of blind flanges in ensuring the integrity and safety of piping systems.

There are a crucial component of the piping system in many industries. It is designed to securely and efficiently seal the end of pipes which makes it indispensable. Starting from dealing with high pressure areas till isolation of sections in pipeline, blind flange is a reliable option to select. It is an easy to apply, install and reliable option with great benefits for industries as an unsung hero. You can indeed choose blind flange to ensure safety measures in your system as a cost effective option.

FAQ’s

What are the specific benefits of using different materials for blind flanges?

The different types of blind flange are served with varied purposes to the applied area. This variation is able to make blind flange versatile in application to specification of installation at high and low pressure areas.

How do I choose the right type of blind flange for my specific application?

Check the dimensions, material of fluid flowing, and pressure and temperature of a particular area. On the basis of these points, you can choose the right type of blind flange.

What are the common issues faced during the installation of blind flanges, and how can they be mitigated?

Commonly, the issue like proper alignment arises when installation of blind flange is carried out. You can mitigate such issues using proper alignment techniques.

Are there industry standards and certifications that blind flanges need to meet?

Yes, there are industry standards and certification of blind flange like ASME B16.5, ASTM A694, MSS SP-44, DIN 2533, ANSI, ASME B16.47, API 6A, EN 1092 etc.