Components like pipe flanges are important in ensuring efficiency and safety in industries. Do you know pipe flanges play a hidden role in connecting pipes? It is basically a flat disc with holes. It won’t look much at appearance but has inevitable power to connect, seal and support pipes with greater efficiency. There are many varied types of flanges available in the market. All of these have specific benefits and significant roles. To select the best suitable option you need to understand differences and uses of these flanges. Unravel the mystery behind pipe flange, its uses and advantages in this blog.

Types of Pipe Flanges

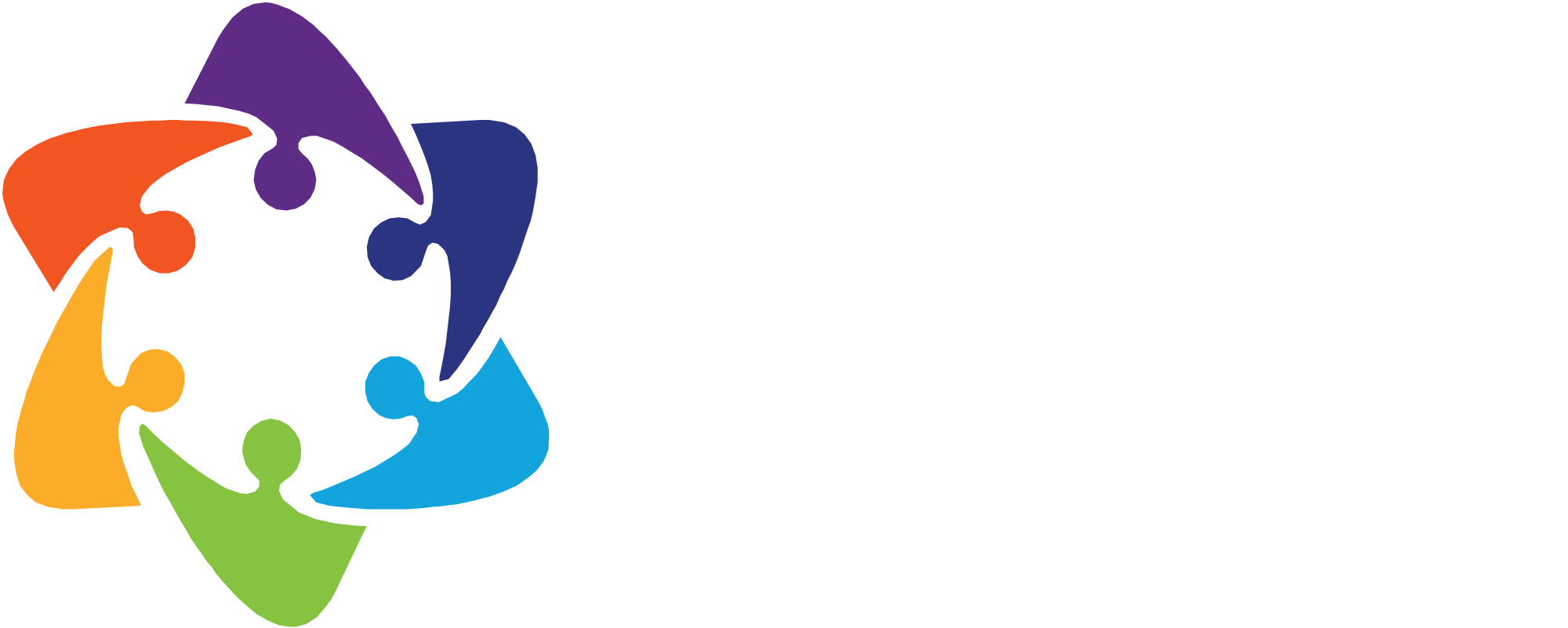

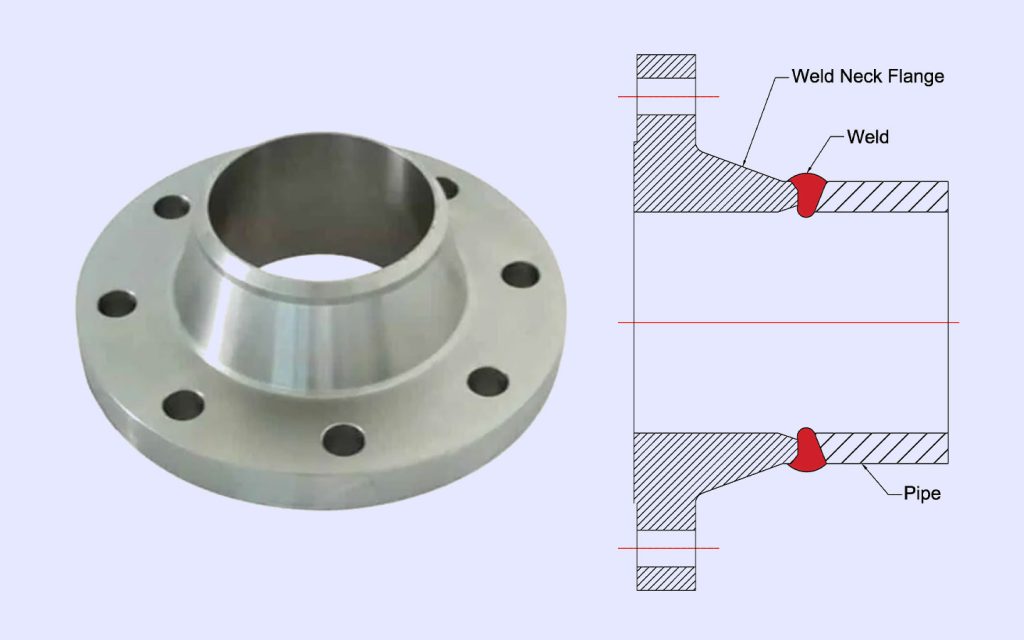

Weld Neck Flanges:

Use of weld neck flange is mainly done for getting high integrity in joints. This flange is commonly used in process piping. It is enough to tolerate high pressure and temperature. You might feel it bulky as well as expensive with respect to other flanges.

1. You should install it in a more spacious area due to the long hub of weld neck flange.

2. Weld neck flanges are available in RF, FF, RTJ etc.

3. Need of expertise to use for fabrications.

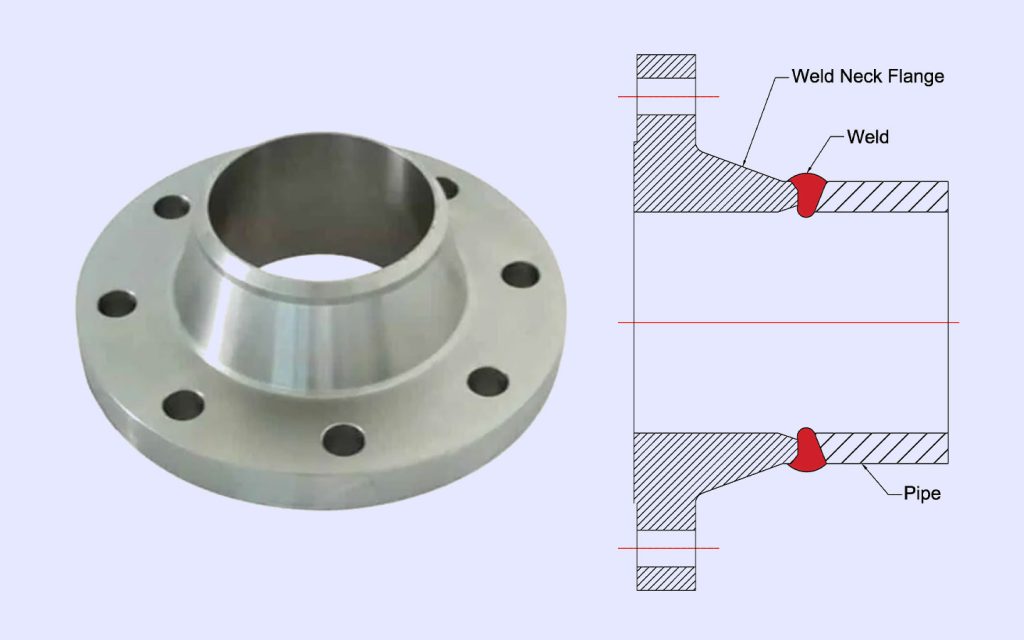

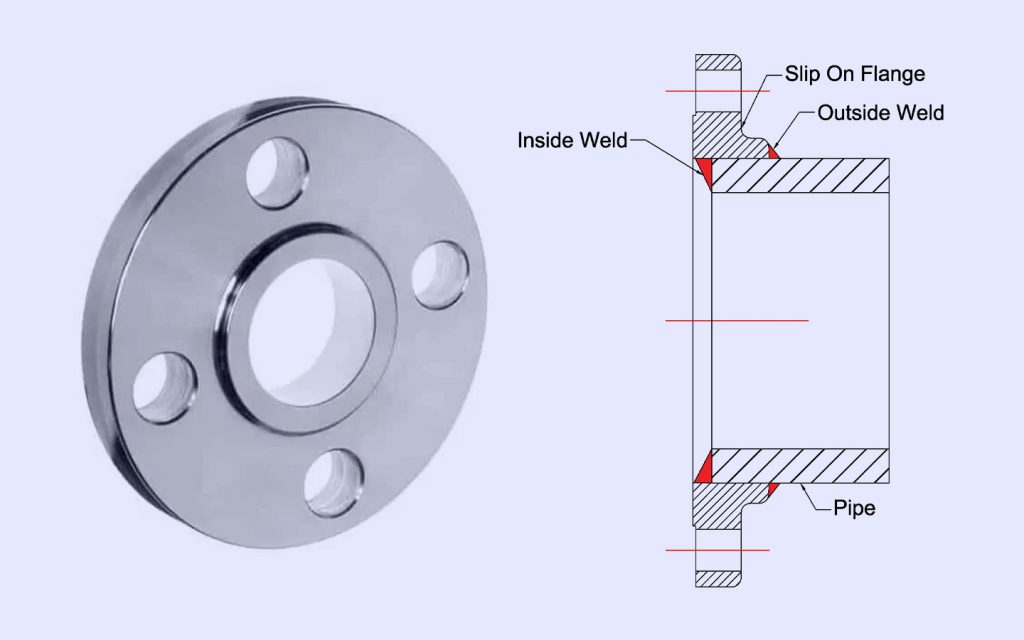

Slip-On Flanges:

Slip-on a flange as name suggest it slips on the pipe. Slip-on flanges have a bore slightly larger than the outer diameter of the pipe it connects to, allowing the pipe to slip into the flange. It slides over the pipe following welding to secure the pipes in place. It is perfectly applicable for low pressure and temperature applications. It is preferable to apply in low stress regions.

1. These pipes possess slightly high diameter and larger size which allows slip-on flanges to slide.

2. It is available in FF, RF etc

3. You can install them at moderate costs.

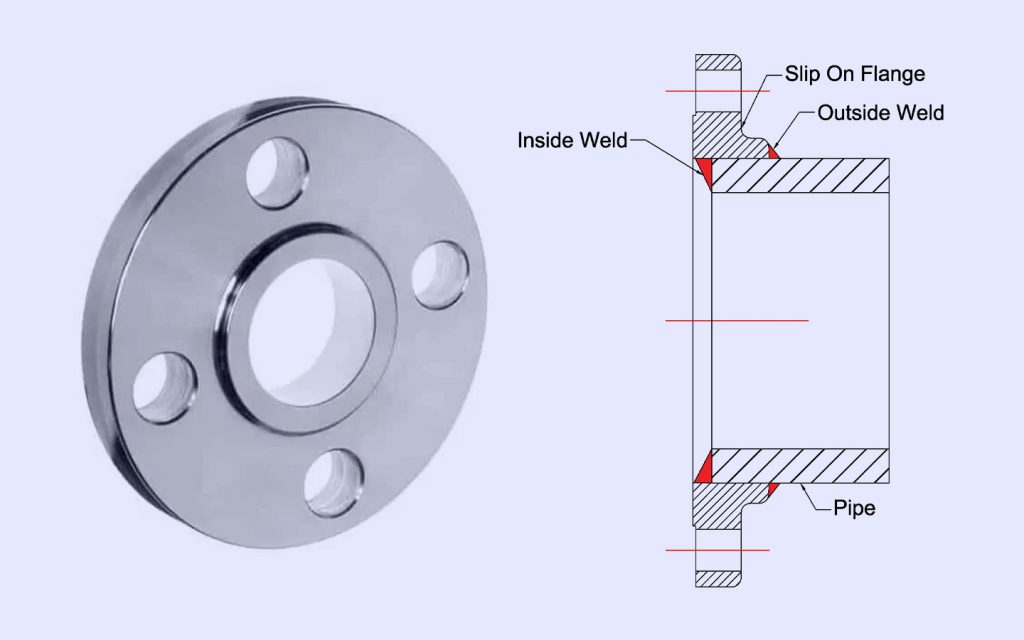

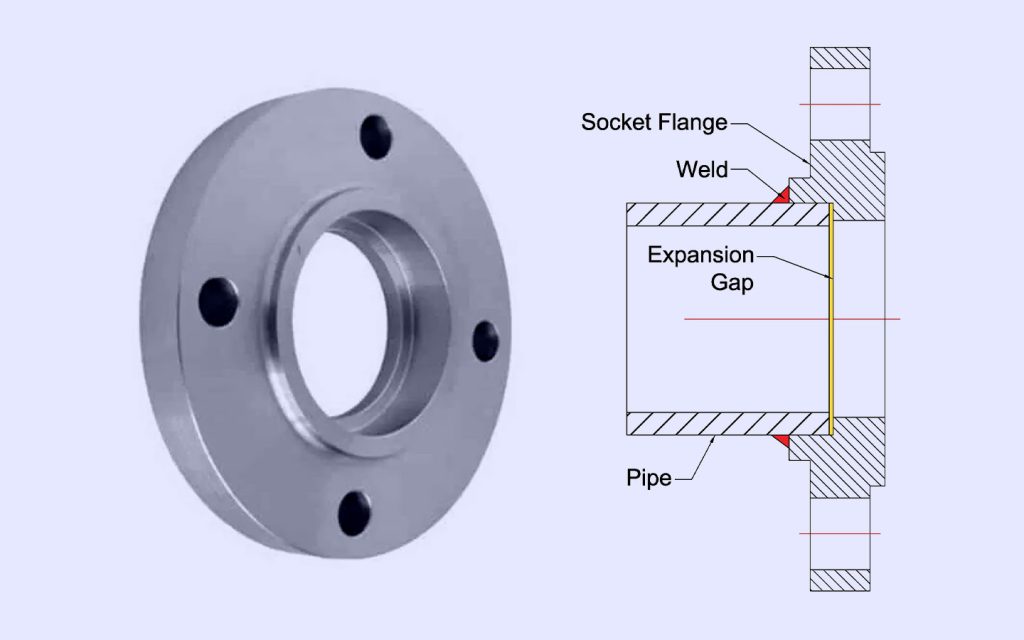

Socket Weld Flanges:

These are proven perfect for the high pressure pipes with smaller size. Insert a pipe in female socket present in socket weld flange following fillet wire is used on top to complete joint connections. Now you can find a very smooth flow of liquid or gas in the pipe after installation of this robust connection.

1. These are appropriate to apply on low pressure and temperature area.

2. Use it for Flat face (FF) or Raised face (RF)

3. The cost of flange and fabrications are much reasonable

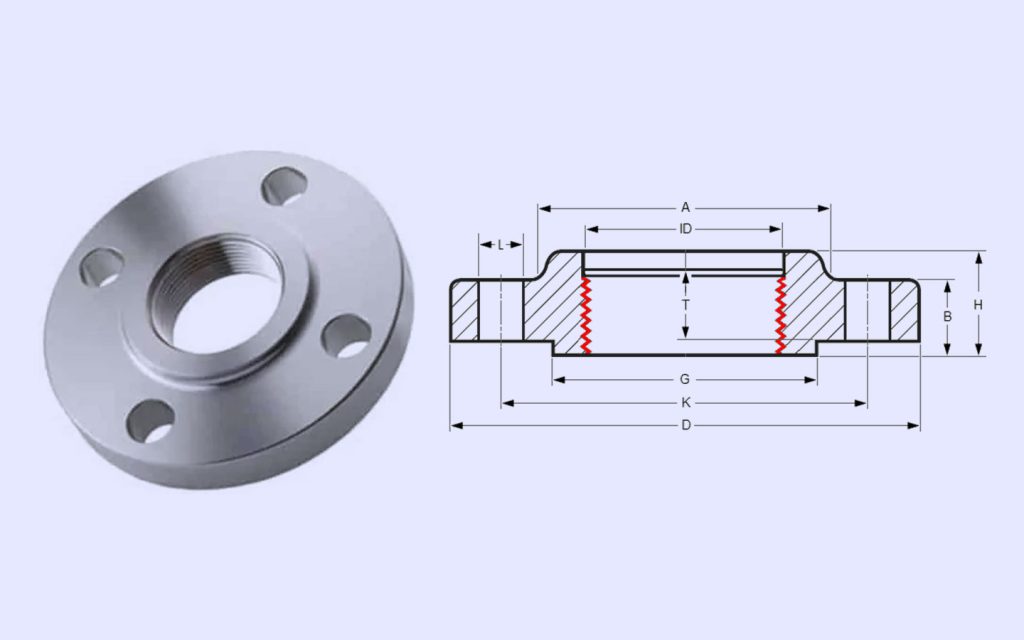

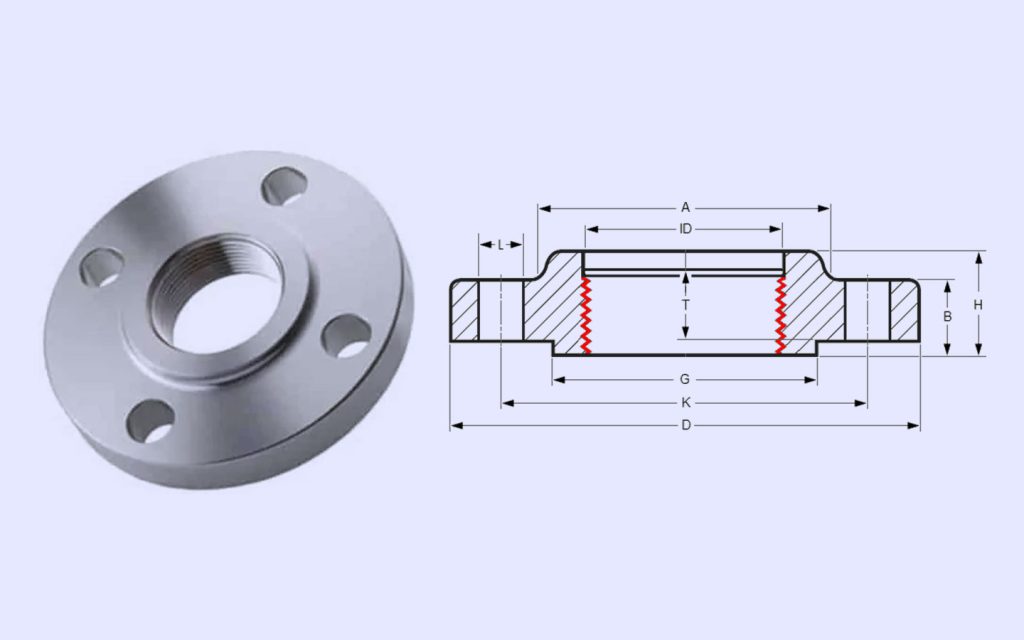

Threaded Flanges:

Do you wonder why this type of flange is named as Threaded flange? Well! It is because there is a presence of thread on the inner side of the pipe flange. These flanges are made to fit in a pipe using matching male thread. Some people also recognize it as a screwed flange. Strictly you have to install it in low pressure areas. But these flanges are not suitable for high temperature and pressure areas.

1. Use it for utility services like water and air

2. You can find in fix size of NPS 4” and below it

3. Proven cost effective

4. Apply only at low pressure areas

5. Find it for FF or RF configuration

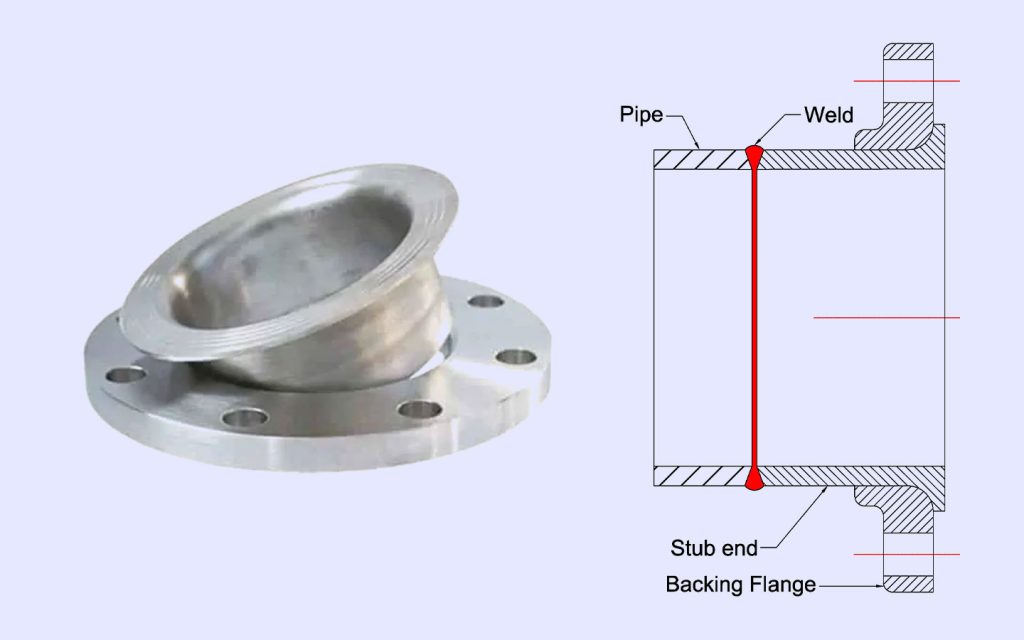

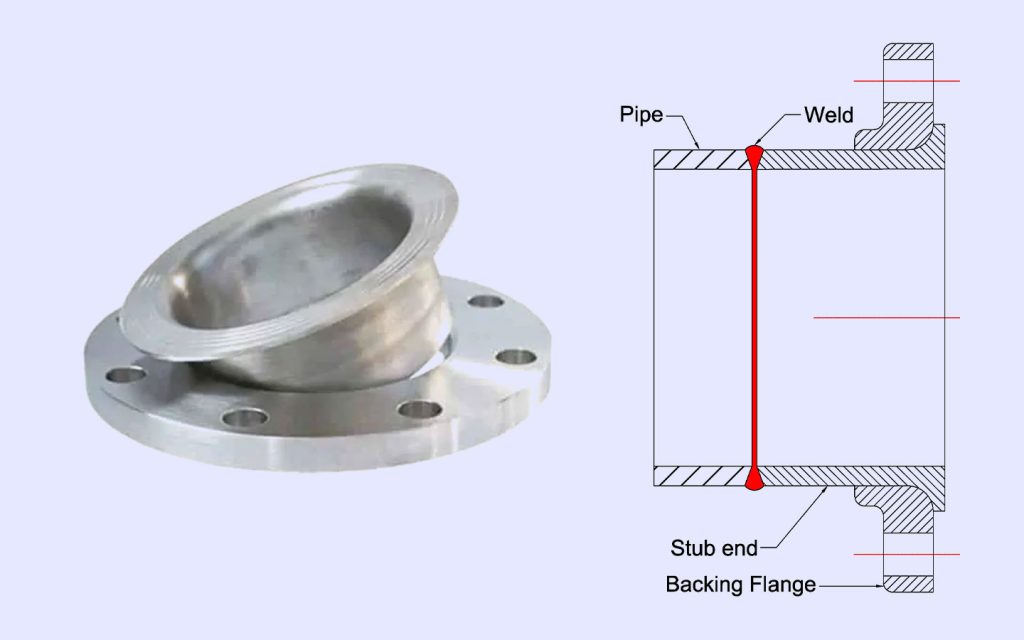

Lap Joint Flanges:

Among all pipe flange types it is considered as most unique because of stub end and backing flange. This feature avails the easy alignment and dismantling of joints made with lap joint flange. It is preferably used in systems which need frequent maintenance. You can apply it for larger or hard to adjust types of areas.

1. The component of lap joint flange is made with carbon steel and hence proven cost effective.

2. There is the presence of butt-weld. Therefore it provides better joining of pipes as compared with socket or threaded types in flanges.

3. It is not suitable for a costly compartment with fabrications and small size as compared to other flanges.

4. Lap joint flange comes with a unique feature which allows connection flexibility. It means you can rotate the pipe freely at a connected part with a flange.

Blind Flanges:

Do you find the absence of a pipe? If yes, use blind flanges to cap off the pipeline. It is useful when there is a need for future expansion of the pipe. Also, you can use blind flanges when you need to stop the system temporarily. You can find these in FF, RF or RTJ types. When you prefer to purchase blind flange, it is important to keep the following considerations in mind.

Appropriate feature for your area

Dimensions

Materials

Key Considerations in Flange Selection

Here are some of the several factors which need consideration while choosing for a particular pipe flange type.

Operating Conditions:

Firstly consider the temperature, pressure and fluid type to know the right choice of flange and its material. Weld neck flanges are featured with superior strength and resistance to deshape. Hence, these are proven perfect for installation with areas facing high pressure and temperature. In a similar way, corrosive fluids require pipes installed with material of corrosion resistance. It mainly includes stainless steel or alloy steel.

Material Compatibility:

You should choose the material of the pipe flange on the basis of fluid or gas transported in it. This compatible step ensures the reliability and compatibility with set up. Also, it works to mitigate frequent maintenance, costlier downtime, risk of leaks, failures and more. Thus, material compatibility is essential to consider when selecting pipe flange type.

Industry Standards:

In installation, the selected pipe flange should fulfil the standards and certification before application. This includes mainly following standards.

ASME B16.5

ASME B16.47

AWWAC207

API 6A

BS-10

EN1092

IS1538, IS6392

JIS

GOST

Also, consider the following certification grades.

ASTM

ASNT

These standards and certification are set to ensure safety and reliability for pipe flanges.

Benefits of Using Pipe Flanges

In industries like gas or oil, pipe flanges are important paramount components to keep things rolling. Check out the benefits to enjoy after installation of pipe flanges.

Enhanced structural support

It supports the pipe to prevent issues like sagging. Also, pipe flanges are perfect to enhance structural integrity. Pipe flanges are very important for pipelines which carry heavy fluids.

Flexibility

Sometimes, it is essential to set the pipelines in accessibly as per location. Here, there is a need for better flexibility of pipe without tackling with adaptors. Pipe flanges are perfect to keep distance from worries of adaptors along with providing high-end flexibility.

Ease of assembly

The process of installation gets simple with pipe flanges. It serves you with a ready made joint area. Now you only need to weld, bolt or screw according to requirement. Hence, it is proven easy to assemble as well as saves you time and cost.

Leak prevention

Pipe flanges are proven best to establish a secure connection at joints. Therefore, it minimises the hazardous escape of fluids. It is very crucial for industries dealing with corrosive or toxic substances to install the pipe flanges.

Alignment

Flanges have swiveling capacity which helps in accurate alignment of pipes during installation. This ultimately reduces the unnecessary stress produced on the system.

Access for inspection and maintenance

It is very easy to maintain, inspect, clean the system installed with different pipe flanges. All of these benefits ensure the longevity of the system.

Best Practices in Flange Connection

Follow these criteria to achieve the best practice in flange connection.

Flange and gasket selections

First choose the area and decide about the substance passing through the pipe. Now select the material and gasket as per fluid. It includes consideration of nature, temperature and pressure from fluid on the pipe. This helps in prevention of leaks. Also, selection of flange based on such criteria ensures compatibility.

Bolt selection

Use equipment like torque wrench for proper tightening of selected bolts. It will help to achieve the even distribution of pressure to prevent any leak or gasket damage.

Placement of gasket

Place the gasket exactly in between the groove of the flange which ensures tight and reliable seal at joints. Misaligned gasket placement is the main cause which makes compromise in integrity with joints.

Flange alignment

Ensure the proper alignment of pipes and flanges during installation which indeed proves important to reduce stress. If not, then this system gets higher chances of leakage and joint failure.

Welding technique

If you need to weld the joints, ensure use of proper welding techniques. It is important to consider the structural integrity of flanges. Also, this mindfulness eliminates the points which are prone to leakage.

Conclusion

In the vast system of piping, pipe flanges are considered as unsung heroes.. Industries starting from petrochemicals till water supply illustrate the indispensable use of various types of pipe flanges. These flanges are beneficial in many ways to ensure safety, efficiency, reliability and conveyance to joints. Remark for the best practices for pipe flange and enjoy steadfast connection with lower maintenance and cost efficiency.

FAQ’s

What are the most common types of pipe flanges?

The most commonly available pipe flanges are slip-on, weld neck, blind, lap joint, threaded or socket weld etc.

How do I select the right flange for high-pressure applications?

The high pressure areas need the flange which can withstand the condition using its strength. Hence, select the flange like weld neck type etc.

What materials are best for flanges in corrosive environments?

Stainless steel or steel alloy are best materials for flanges in corrosive environments.

What are the advantages and disadvantages of different flange types?

The advantage of most flanges comes as strength, longevity, leak proof, ease to install and dismantle, flexibility, withstand to temperature and pressure etc. But some of them require more space or are found costlier to install which are considered as disadvantages.

Are there specific standards or certifications required for flanges in certain industries?

Yes, there are specific standards like ASME B16.5, ASME B16.47, AWWAC207, API 6A and certifications like ASTM, ASNT etc. All of these are necessary to ensure safety and reliability for pipe flange.