Flanges are specifically designed to make connections of the pipe with different sizes. There is revolution in different classes and grades available in different types of flanges. Among all these class 150 flanges are considered highly usable in different industries. It basically belongs to class 150 in ratings. Here you can explore more details of class 150 flanges, its types, specifications, applications, tips for installation and maintenance etc. After exploring the entire blog, you will definitely choose the ideal flange according to your requirement.

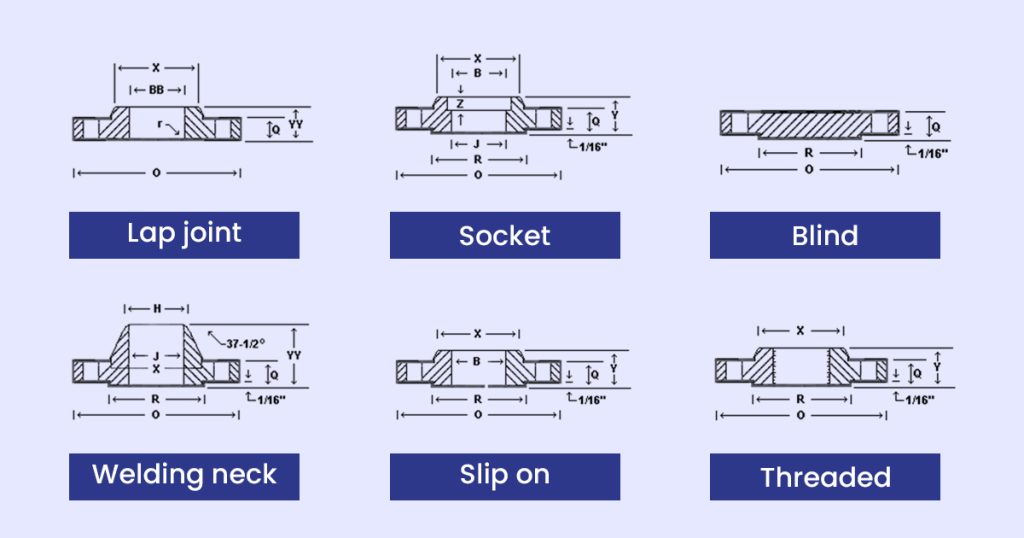

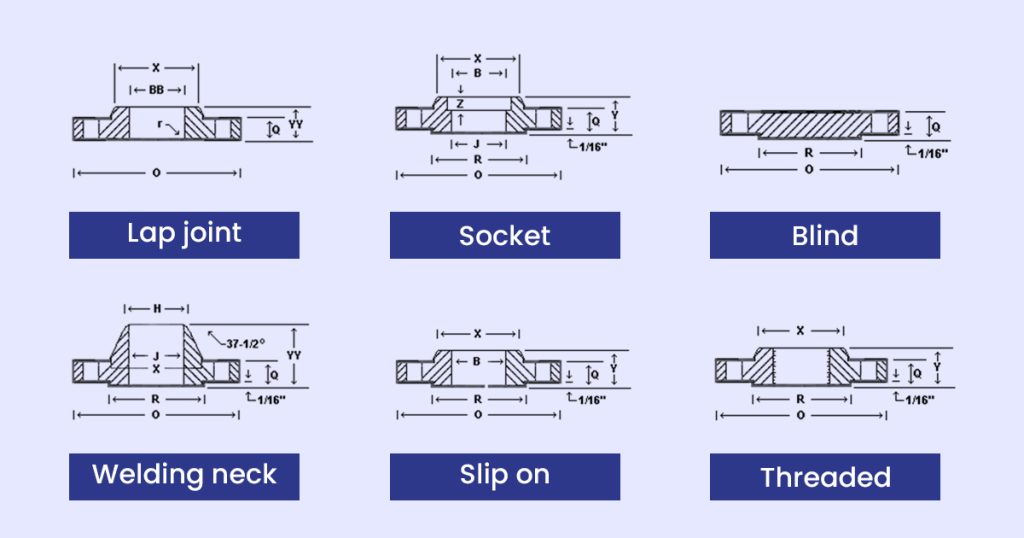

Types of Class 150 Flanges

There are six main types of the flanges available in the market. Let’s make a brief overview of each of them.

Weld Neck

It is specifically recognized for their longer neck. These are welded with the butt to reduce turbulence and erosion on the piping system. The significant role of the flanges here is to distribute the stress at the bottom relocating it from the pipe. This ultimately will reduce the high stress concentration on particular parts of the piping system. The flanges need to get arranged parallel to fittings at time of installation. Flanges placed on opposite ends should have similar size of bolt and direction for perfect fitting.

It is installed at a place with repeating bends

A Welded neck can easily handle the area with wide fluctuations with temperature and pressure ranges.

These flange connections are enough to withstand volatile and hazardous fluids.

Slip-On

These have thinner design for specially installation at low pressured areas. The flange is designed to have a slight more inner diameter as compared to pipe’s outer diameter. It will make the pipe slip-on into the flange easily. Following fillet weld is applied on the connected area on top and bottom areas. This leads to formation of the connection with enhanced strength and leak proof properties. It is very easy to install the slip on flanges without any need of technical knowledge. Hence, it is proven as a cost effective option. Yes, it surely saves the cost of installation but add on some due to additional use of fillet welds.

These are typically installed in firefighting water lines and cooling pipes in industries.

It is ideal for installation in process lines like water, chemical , oil, gas etc.

Blind

These are purposefully installed in an area to prevent the flow of fluids in the pipe using its design. The design contains a lack of inner holes which ultimately provides the secured barrier for flow of fluids. Due to this, it becomes a cost efficient option and easy option to carry out various pressure tests for joints. Use this flange and safely install new pipelines, valves as it can stop the flow of fluids easily.

You cannot imagine any repairs, shutdowns in the system without use of blind flanges. Yes, the shut off valve is a possible replacement for the blind flange. But imagine the amount of fluid it wastes till you reach the valve. It becomes an incredibly difficult situation to handle when the valve would not be able to withstand pressure. Hence, on a safer side industries preferably use blind flanges to avoid any accidents.

Used mainly for testing the pressure on pipes.

Separate the piping system with blind flange for making access points.

Blind flanges can help to separate or seal the piping system temporarily for repairs or even permanently.

Socket Weld

Socket welds are made with a simple design to install at small sized areas needed to tackle the high pressure conditions. But these joints are not effectively able to withstand highly corrosive fluids. You only need to insert the pipe into socket weld and add a fillet weld around and get the job done.

It is mostly used in hydraulic pipes.

Lap Joint

You might also find lap joints recognized as loose ring flanges or back-up flanges. Lap joints are designed in a way which slides over the flanges with a stub end. Does your system require frequent dismantle and cleaning practices? If yes, then lap joints designed with stub ends enable you to enjoy this feature in a cost effective manner. These flanges get swivel with bolt holes. It means the joints never come in direct contact with the fluids passing via pipe. Hence, it is proven a durable option for piping systems which need to transport corrosive fluids.

It is ideal for area with low pressure application

Applicable in areas which require frequent cleaning and dismantling.

Threaded

It is preferably installed in an area with a low pressure pipe made with thick walls. Once applied it becomes easy to connect and disconnect the piping system for various reasons. The main benefit here is to reduce the downtime for carrying maintenance and adjustments. Firstly, the female thread is screwed with the external thread of the pipe. Later, the flange and pipe are connected to get the secured connection. Also, there is no additional need for welding on such joints.

It is applicable to areas which deal with explosive, flammable or hazardous fluid where welding seems dangerous.

Threaded flanges are ideal for such a restriction area where welding the connection of pipe and flange is not possible.

Specifications and Standards

ASME/ANSI B16.5 compliance

Flanges types and sizes are available in different versions in the market. But you need to select one based on the specification of the standards on grade. ASME B16.5 is the basic standard which you need to consider before finalizing the one flange for your application.

ASME stands for American Society of Mechanical Engineers who has designed the ANSI B16.5 standard which indicated the dimensions, material grades, tolerances and temperature vs pressure characteristics so that one can choose as per his requirements.

B16.5 has flange dimensions up to 24” that is 600NB. For size above 600NB ASME has created B16.47 standard which gives detailed engineering data sheets for flanges above 600NB. These B16.47 is further divided into series A and Series B based on the pressure characteristics.

Dimensional charts and pressure ratings

There are different ranges with higher pressure classes as mentioned below

150 lbs

300 lbs

400 lbs

600 lbs

900 lbs

1500 lbs

2500 lbs

Materials and coatings

Which is the perfect material for your flange steel or plastic? Well! In this case, you should select the material of the flange based on the area of its application. For example, if you primarily deal with low pressure and non corrosive fluids then why to invest in corrosion-resistant materials. Further before finalizing any of the material you need to match it with standard grades for ensured sealing. Let’s check out the commonly available materials and coating in flanges.

Carbon steel

Carbon steel flanges are made using carbon as primary alloy in composition of material. Carbon steel has preferably high hardness and strength making it ideal for high temperature area application. These materials are available in different ranges according to carbon content from 0.16-0.29% till 1-2% of carbon. If you choose carbon steel above 2% of carbon content it is known as cast iron.

Alloy steel

Here, you can preferably add any element to make alloy steel which proves ideal for your applied area. Generally molybdenum and chromium are used as alloy. Merging different elements in alloy steel, it will increase strength, corrosion resistance, ductility and machinability etc properties. In ASME B16.5 standard various alloy steel and its characteristics are given as charts so one can choose better option as per his application.

Stainless steel

Stainless steel is the result of chromium used as alloy in preparation for about 10%. Chromium present in the composition of the stainless steel imparts the corrosion resistance properties. Hence, you can indeed choose stainless steel as the ideal choice for areas dealing with corrosive fluids which need more strength. Don’t forget to match the grades of stainless steel before you actually apply to the system.

Cast iron

Cast iron is the result of a combination of alloys like carbon, silicon etc. This material has properties like machinability, wear resistance, castability and fluidity. But these get brittle in texture when exposed to lower melting points.

Aluminium

It is considered a medium strength metal having low density. These are more resistive to corrosion as compared with carbon and other alloy steels. It is malleable and ductile, proven ideal for piping systems facing corrosive fluids. Hence, it is ideal for the application having high strength and low weight as in irrigation. But its too much costly as the raw material is aluminium.

PVC

PVC composed flange is proven cost effective and durable option in piping systems. PVC pipe has the advantage of getting chemical and corrosion resistance. Further, with a mixture of alloys you can develop a better version of flexible and softer material. These are mostly useful in domestic plumbing and other agricultural industries. It is proven lightweight and easy to install options.

Applications and Use Cases

Class 150 flanges are typically used in different industries for connection with different valves, pumps, pipes and more. Application of the flanges is dependent on the specific pressure and temperature conditions. Here are some of the important industries which need class 150 flanges application.

Chemical industry

Class 150 flanges are employed for the different chemical processing plants. It is essential for handling corrosive and other types of hazardous fluids.

Oil and gas pipelines

Oil and gas pipelines need the transport for crude oil, refined products, natural gas and more. Therefore, it needs installation of the proper class 150 flange dimensions in mm fore refineries, petrochemical plants and more. Mostly weld neck flanges are preferred in oil and gas pipelines.

Water treatment facilities

Class 150 flanges are used in water treatment facilities for proper water distribution of sewage and more.

Nuclear power plants

Nuclear power plants generally deal with highly reactive materials. Therefore, it needs to make use of class 150 flanges which provide a leak proof environment. For Nuclear power plants alloy steel material is used.

Selecting the Right Flange

You need to consider selection of various class 150 flanges based on specific factors mentioned as follows,

Pressure ratings

These are specially designed for making applications with low pressure areas. Hence, you can select the one suitable considering this fact. At ambient conditions(i.e. 100 degree Fahrenheit or 38 degree Celsius these flanges can withstand 270 psi but if the temperature goes higher ,the pressure capacity decreases. For 204 degree Celsius it reduces to 180 psi and for 427 degree Celsius it becomes 75 psi only. So temperature vs pressure graph we need to study before selecting the 150#.

Material selection

Ensure the compatibility of the material selected for the flange. It should indeed match with piping material as well as the fluids passing via. Generally, carbon steel, stainless steel and alloy steels are used as material. In case of corrosion resistance needs, go for special stainless steel materials matching the grades.

Temperature and pressure

Verify if the flange could withstand the pressure and temperature produced due to fluid passing through the piping system.

Installation considerations

Make sure that flange is properly installed with proper alignment and fittings. This will avoid the chances of flange failure as well as crack in the seal.

Dimensions and standards

As per class 150 flange dimensions in mm pdf these are available in the form of flat face, raised face or ring joint types. You can select a particular based on requirement. Prefer to choose the bolt pattern which could match and screw with mating flanges. Above all, always ensure standard compliance like ASME and more.

Installation and Maintenance

Installation best practices

Class 150 flanges are installed to deal with low pressure areas. Hence, it is important to note proper installation and maintenance of the same for long service life. Check out some tips to consider as follows:

Inspection of the flange and gasket

Before you are set to install, prefer to check persistence of any cracks on flange and gasket material. It also includes signs of any corrosion or damages. Also, make an eye on compatibility of gasket material with fluid flowing through the piping system.

Clean mating surfaces properly

Remove all visible dirt, oil or debris present on the surface of the mating flanges. This will enable me to make a good seal.

Check proper alignment of flanges

If flanges are not properly aligned it might develop a stress on the piping system which ultimately cracks the connection. Hence, you need to ensure the proper alignment of the flanges using tools and techniques during the tightening process.

Use correct bolts and torques

Select the bolts as similar dimensions of flanges and tighten these in criss cross manner. This will give an even distribution of the stress on the system to avoid failure. Further, you can make use of the torque wrench as per specified standard of flanges.

Avoid over tightening of bolts

Overtightening of the bolts might damage the surface of the flange or gasket. In this case, you can follow the torque characteristics specification mentioned in the manufacturer list.

Verify the alignment once after tightening

Once you finish the instalment, verify the tightening of the bolts to prevent any gaps in the system with proper alignment.

Regular maintenance and inspection procedures

Regular inspections

Regular inspection is essential to check the presence of corrosion, signs of damage, leaks and more. Pay special attention to the sealing of flanges and gaskets.

Monitor on leaks

Periodically monitor the system for prevention of leaks in the system. If you find any sign, immediately address it to avoid any accidents.

Check bolt tightness

On a regular basis, ensure the enhanced tightness of the bolts. Tighten them up if essential matching the value of torque according to specification.

Replace gasket at specific intervals

Prefer replacement of the gasket at specific intervals. It is most essential if the system faces frequent vibrations or thermal cycles.

Clean the flanges during maintenance

Cleaning of the flanges is a crucial part of maintenance service. Replace all damaged components for longevity of the system.

Make use of compatible materials

Again the material of the gasket and bolts is important to ensure the compatibility of the piping system.

Document maintenance activities

Keep detailed records for all inspection and maintenance activities along with repairs performed. It will help to stay updated on the performance of sealing with flanges and identification of recurring issues.

Tools and Resources

Class 150 flanges are the widely used option for connection of pipes, valves and various other equipment. But these require the help of proper tools and resources for perfect installation and handling.

Software for flange selection

ANSYS

It is considered as the finite element analysis (FEA). It helps to stimulate the properties of thermal flange, stress, vibrations and more.

Solid works

This particular software enables the visualization of the design and modelling of the flanges in 3D manner. It will allow detailed ideas for proper connection of flanges.

AutoCAD

It is one among the advanced software tools used to make out for the designing of 2D and 3D images of flange sealing.

CATIA

This software allows the design of the complex structure of flanges.

CAESAR II

It is used to inspect the stress analysis on the piping system. Using this application you can ensure the proper integrity of the system handling other loading conditions.

Industry standards

ASME (American Society of Mechanical Engineers)

It provides the standards of the flange dimensions, materials and pressure ratings for industrial fittings.

ASTM (American Society for Testing and Materials)

ASTM offers different specifications of materials used in composition for flange. Also, it provides the grades to steel which enables selection of material according to requirement.

ISO (International Organization for Standardization)

It offers the standards for flanges and materials at international level. It also indicates compatibility with other nation’s standards.

Conclusion

Class 150 flanges are proven perfect for installation at low pressure areas. These are available in different types which can match according to the needs of a particular area. Further, standardization provided on class 150 flanges enables one to select for a specific grade of flange. Due to such benefits, many industries like oil and gas, water treatment, chemical plants, food processing, HVAC and more have applied class 50 flanges. A final tip for all buyers is to seek the need and choose the flange appropriately following factors to consider while selection. Lastly, periodic maintenance will help to ensure longevity of service.

FAQ’s

1. What are the different types of Class 150 flanges available (e.g., weld neck, slip-on, blind)?

There are different types of class 150 flanges available in the market like weld neck, slip-on, blind, threaded, socket, lap joint and more.

2. How to install Class 150 flanges correctly?

Firstly select the appropriate material of the flange, following bolt and gasket. Tighten bolts in the proper way using torque specification and make proper alignment of flanges. Verify lastly the integrity of sealing once you finish the installation of class 150 flanges.

3. What are the maintenance and inspection procedures for these flanges?

It is important to make proper alignment of the mating flanges with bolts. Further, schedule the periodic inspection and maintenance to seek for any signs of danger, leaks etc.

4. Are there any tools or software that can help in selecting the right flange?

Yes, you can use software’s like Solid works, AutoCAD etc. which can help for proper selection of flanges.

5. How do the materials (e.g., stainless steel, carbon steel) affect the performance and longevity of the flanges?

The material of the flanges is important to consider to ensure longevity of the system. It is because of the need for corrosion resistance, tolerance for high and low pressure etc.