One of the most important criteria in deciding design, installation and manufacture of pipe fittings is ASME B16.5 standards. Here you can explore the importance of ASME B16.5 standards in shaping different pipe fittings in industries. This blog will enable you to make a deeper understanding of ASME B16.5 flange standards and dimensions. Hence, you can easily explore its specification and impact in deciding the integrity of the piping system in industries.

What are ASME B16.5 standards?

The American Society of Mechanical Engineers is known in shorter versions as ASME. It is published to set specific outlines in pipe flanges and fittings with following tolerance level, dimensions, testing requirements, materials etc. These standards ensure that each of the flange parts made or installed in industries is manufactured with proper consistency and compatibility. The flange part compliance with ASME B16.5 standards helps ensure interoperability, safety and reliability of piping components used in industries.

The standard provides clear guidelines to all manufacturers to design the flange with specific design and fabrication. Hence, a flange part made with these standards ensures to maintain functionality and integrity with the piping system. Adhere to these specifications mentioned in the outline of ASME B16.5 to produce the flange parts which meets quality standards. These standards are crucial to follow to ensure a safety of the system after installation in industrial areas to withstand the extreme conditions.

In addition, compliance with standard can help to facilitate production of flange components and fittings with interoperability and consistency. Thus, flange components manufactured with following ASME B16.5 standards are always efficient and seamless in operation after installation.

What is ASME B16.5 material grade?

A bit of exploration of ASME B16.5 flange material grade will help you to set a higher reliability of flange fitting in the piping system.

Material used for flange and flange fittings

Only those material listed in table 1A of the ASME B16.5 standard is advised to use in manufacture of flange and flange fittings.

Plate and flat bar materials are specifically only used in production of blind flanges. Also, these are sometimes used in reducing flange without any hub.

The flange components and fittings are advised to manufacture whole as a single piece out of a specific material. This means according to standard it is not allowed to assemble multiple pieces of the flange together with welding or bolting.

Process of manufacturing

It is important to manufacture the flange components and fitting using compressive plastic hot working operations. This particular process will give a specific shape and size to flanges.

The process of manufacturing creates a wrought material structure. Also, it ensures the flow of the metal in a specific direction which makes the surface of flange stress resistant to provide better service.

Recommended bolting materials

To know the list of bolting materials refer to table 18 provided in the ASME B16.5 standard guideline.

Compatibility of material

Compatibility of material is decided on the basis of the list mentioned in Section II of Pressure vessel code and ASME boiler. As per the standard it should meet the requirement of material grade as per ASTM specification class.

How many updates are observed in ASME B16.5?

You can find the latest five different updates in ASME B16.5 standard.

ASME B16.5 -2020 edition

It includes utter details starting from dimensions, tolerance level, marking, testing, materials, temperature, pressure ratings etc for pipe flange and fitting. You can see the specification of different flange class designations that are mentioned in both metric and U.S. customary units. These standards are limitedly applicable to only a few types of the flange fittings. It includes forged, cast, blind flanges, reducing flange composed of plate or forged materials etc.

ASME B16.5- 2017 Edition

This version mainly includes the subsequent updates in the list. It is basically a revised and updated version improved mainly on the basis of feedback from different industries. Also, it includes using some of the latest innovations and practices made in technology and engineering fields.

ASME B16.5 -2013 edition

ASME B16.5 standards are updated and introduced with new refinements along with clarification. All of such changes are best to observe more accuracy and consistency in manufacturing of flange pipe and other fittings.

ASME B16.5-2009 edition

It is a bit of a traditional version of standards. It only incorporated the changes which were most essential and needed to enhance the working of flanges in the piping system.

ASME B16.5-2003 edition

It is the very first updated but earlier version which enables one to address the new innovation seen in the industrial world from traditional days.

Scope and Limitations of ASME B16.5 standards and dimensions

It is important to have proper understanding about ASME B16.5 standards and limitations in order to apply the flanges in the correct way in the piping system. Check out this section to know in detail about what all criteria are included under ASME B16.5 standards to get more clarifications. Also, check out some of its limitations to ensure the understanding of the boundaries of these standards.

Pressure-temperature ratings

ASME B16.5 standard list mainly includes pressure ratings, tolerance level, marking, testing, dimensions, materials and other credentials. These all criteria make the best version of flange parts and fittings for the piping system.

Flanges

The standard peculiarly converts the flange part with rating of class like 150, 300, 400, 900, 1500 etc in size of NPS 1/2 till NPS 24. Also, it covers the designation of rating class 2500 in size of NPS ½ till NPS 12. These are mentioned in both U.S. customary and metric units.

Flanged fittings

This standard also converts the flanged fittings in different class designation which comes from 150 and 300 ratings in size from NPS ½ to NPS 24 in both U.S. and metric units.

Additional inclusions

Flange bolts and gaskets and other types of joints are very important to select according to ASME B16.5 standards. It is because these parts play an important role in ensuring enhanced performance and proper assembly of flanges in the piping system.

Limitations

The ASME B16.5 standard is peculiarly applicable only for the flanges and fittings which are made from forged or cast materials. Also, it is applicable for blind flange or reducing flanges composed of plate, cast or forged materials.

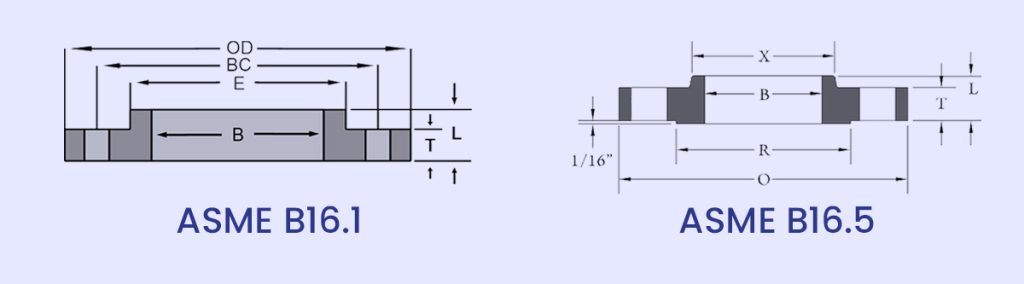

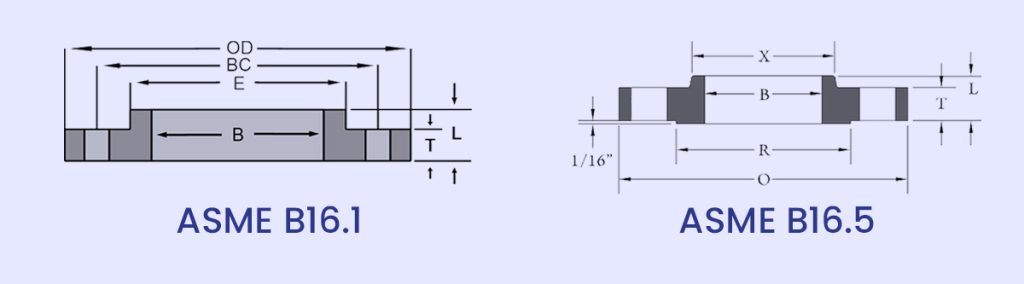

What is the basic difference between ASME B16.1 and ASME B16.5?

The variation and type of the components of flanges that are covered under these standards are different which create a basic difference in between both standards. Generally, flanges made with following ASME 16.1 standards are made from cast iron materials. However, flanges manufactured under ASME 16.5 flanges are made with stainless steel or steel materials.

ASME B16.1 covers the detail of flange fittings made from cast iron along with their specific dimensions, materials and tolerance levels. But ASME B16.5 covers a wider range of detail for production of flange fittings made from different materials except that of cast iron.

Among both the standards, ASME B16.5 covers the broader range of flange fittings made with different materials and types. Whereas, ASME B16.1 is particularly applicable only to flange fittings made with cast iron.

Benefits of ASME B16.5 standards

ASME B16.5 is a widely applicable standard in different industries for installation of flange and fittings in piping systems. Here side you can find many of the benefits attached with ASME B16.5 standards as follows:

Consistency and uniformity

ASME B16.5 provides a particular standardized approach for production of flange fittings with maintaining specific quality and consistency. It provides the guideline to flange manufacturers to produce the flange with the same dimension. This uniformity helps in increasing the facility of maintenance and replacement of the different parts.

Safety and reliability

The standard helps in providing for different pressure and temperature ratings, materials to use and more. When flange manufactured as per standards, it can easily withstand the harsh conditions at point of installation. All of these could increase the reliability and safety in the piping system ultimately minimizing risk of accidents, leaks and failures.

Interchangeability

All the flange components manufactured following the guidelines of ASME B16.5 standards are always compatible with other parts made with similar guidelines irrespective of manufacturer. This feature of interchangeability decreases the complexity at time of installation. Also, it reduces the risk of misalignment or misfits of flange parts.

Global acceptance

ASME B16.5 standards are recognized and accepted worldwide. Hence, it becomes easier for the companies to set their place in the international market. Also, these standards provide the opportunity to companies for manufacturing of the product that meets global standards.

Efficiency in design and construction

The standard covers the detailed specification of the design and process of construction of the flange parts and fittings. Hence, it utterly reduces the time required to select the different parts for flange manufacturing in the piping system.

Regulatory compliance

Many of the regulatory bodies and other industrial codes have compliance with ASME B16.5 standards. Hence, a company needs to only follow this standard to meet legal and regulatory requirements.

Cost savings

Flange parts manufactured with ASME B16.5 standard doesn’t require the need for custom components to ensure compatibility. Thus, you can find cost savings for custom fabrication, long lead times, inventory and more.

Enhanced performance

Components designed with ASME B16.5 standards are specifically engineered to meet up the harsh environmental conditions and give optimal performance. Therefore, flange parts give a reliable and efficient functioning at operation of industries which ultimately improves the performance of the entire system.

Conclusion

ASME B16.5 standards serve as vital guidelines to piping engineers for manufacturing of flange and fittings with high functionality and integrity. Adhere to the guidelines mentioned as per ASME B16.5 standards to make efficient operation of industrial areas. Piping designers totally rely on this standard while selecting flange fitting for their need according to tolerance, dimension and materials. Engineers refer to the standard for ensuring compliance of flange parts with pressure and temperature rating class. Inspector assigned for maintenance and checking verify the ASME B16.5 standards tag on installed flange and fittings. In short, it is important in industrial areas to ultimately check the safety and reliability of the piping system.

FAQs

What is the size of the ASME B16.5 flange?

ASME B16.5 flanges are available generally in about ½” to 24” in size diameter for about 1/16” raised face.

What are the different dimensions of ASME B16.5?

ASME B16.5 have different dimensions as 150, 300, 400, 600, 900, 1500 and 2500 available in NPS ½ till NPS 24.

Is ASME B16.5 same as ANSI B16.5?

Yes, many of the people ASME B16.5 is similar to ANSI B16.5. Most of the time American National Standards Institute [ANSI].

What is the size of the raised face of ASME B16.5?

ASME B16.5 raised face flanges have a height of about 1.6mm to 1/16 inches which follow 150 to 300 pressure classes.

What is the basic difference between ASME B16.5 series A and B?

Series A includes different types of joints like weld neck, ring, blind etc. However, Series B makes a primary focus for blind and weld flanges.